Nov . 07, 2024 21:53 Back to list

Column Formwork Manufacturing Solutions for Construction Industry

The Evolution and Significance of Column Shuttering Box Factories

In the ever-evolving construction industry, the demand for efficiency, safety, and quality has led to the emergence of various specialized manufacturing processes, one of which is the production of column shuttering boxes. These critical components play a vital role in the creation of reinforced concrete structures. This article will delve into the significance of column shuttering box factories, exploring their evolution, manufacturing processes, and impact on modern construction practices.

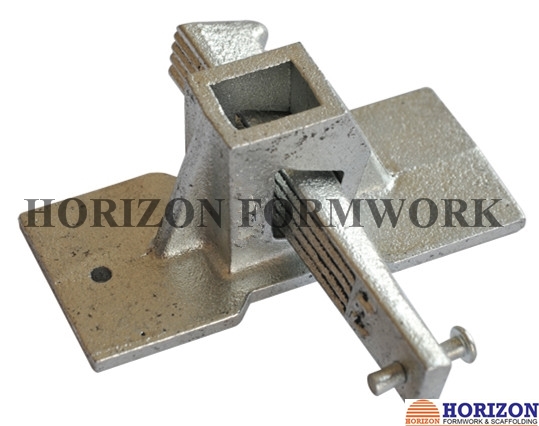

Understanding Column Shuttering Boxes

Column shuttering boxes, often referred to as formwork systems, are temporary structures used to support and mold concrete into predefined shapes prior to it hardening. The primary purpose of these boxes is to ensure that the concrete is poured and cured in a controlled manner, allowing for the creation of sturdy and accurately shaped columns. The quality and design of these shuttering boxes directly affect the efficiency of a construction project, as well as the overall quality of the finished structure.

The Evolution of Column Shuttering Box Manufacturing

The manufacturing of column shuttering boxes has advanced significantly over the years. In the past, constructions relied heavily on traditional wooden forms, which were labor-intensive and often resulted in inconsistencies due to variations in materials. As technology progressed, the construction industry began adopting steel and aluminum shuttering systems, which provided greater durability, reusability, and precision.

Modern column shuttering box factories leverage advanced manufacturing techniques, including computer-aided design (CAD) and precision engineering. These technologies enable factories to produce customized shuttering solutions that cater to specific project requirements. Additionally, the rise of prefabrication has streamlined the manufacturing process, allowing for faster production times and reduced on-site labor costs.

Manufacturing Processes in Shuttering Box Factories

column shuttering box factories

The process of manufacturing column shuttering boxes involves several key steps. It typically begins with the design phase, where engineers and architects create detailed specifications for the required shuttering system. Once the design is finalized, raw materials such as steel or aluminum are sourced.

The next phase involves cutting, shaping, and assembling the materials into the desired formwork. Automated machinery and robotics are increasingly employed in this stage to enhance precision and efficiency. After assembly, the shuttering boxes undergo rigorous quality control checks to ensure they meet safety standards and performance requirements.

Finally, the completed products are treated for durability, often with protective coatings to enhance resistance against weather elements and wear. Factories not only focus on producing high-quality shuttering boxes but also prioritize sustainability by implementing eco-friendly practices, such as recycling materials and reducing waste.

The Impact on Construction Practices

The advent of column shuttering box factories has had a profound impact on construction practices. The increased availability of high-quality shuttering solutions has enabled faster and more efficient construction processes. As a result, projects can be completed in significantly shorter timeframes, which is crucial in today’s competitive market.

Moreover, the use of modern shuttering systems contributes to improved safety on construction sites. Well-engineered formwork systems minimize the risk of failures that can lead to accidents, thus safeguarding workers and enhancing overall project integrity. Furthermore, the precision afforded by advanced manufacturing techniques ensures that structures are built according to specifications, reducing the likelihood of costly rework and delays.

Conclusion

In conclusion, column shuttering box factories have become indispensable components of the modern construction landscape. Their evolution from traditional wooden forms to sophisticated, engineered solutions reflects the industry's commitment to enhancing efficiency, safety, and sustainability. As construction projects continue to grow in complexity and scale, the role of these specialized factories will remain critical in shaping the future of our built environment. The significance of column shuttering boxes is not only in their immediate impact on construction processes but also in their contribution to the long-term viability and resilience of structures worldwide.

-

Formwork Spring Clamp Factories | Quality & Durable Spring Clamps

NewsAug.31,2025

-

Adjustable Heavy Duty Props for Slab Formwork - Max Load & Safety

NewsAug.30,2025

-

Premium Formwork Wing Nuts & Tie Rods | Factory Supplier

NewsAug.29,2025

-

Expert Ringlock Scaffolding: Durable, Safe, Efficient Solutions

NewsAug.28,2025

-

Ringlock Scaffolding: Strong, Safe & Efficient Solutions

NewsAug.27,2025

-

OEM Column Formwork: Circular, Curved & Inclined Solutions

NewsAug.26,2025