Nov . 21, 2024 04:38 Back to list

concrete pillar formwork companies

Exploring Concrete Pillar Formwork Companies Innovations and Trends

Concrete pillars are critical structural components in various construction projects, from residential buildings to massive infrastructure like bridges and skyscrapers. The formwork used to shape and support these pillars during the curing process is vital for ensuring structural integrity and achieving desired architectural designs. In recent years, the landscape of concrete pillar formwork manufacturing has evolved significantly, driven by advancements in technology, sustainability considerations, and changing construction practices.

The Importance of Quality Formwork

Formwork serves as a mold for pouring concrete. It plays a crucial role in determining the quality and strength of concrete pillars. High-quality formwork not only ensures the right dimensions and shapes but also influences the finish and overall aesthetic of the structure. Companies specializing in concrete pillar formwork must focus on precision engineering, durability of materials, and innovative design solutions. This need has fostered competition among manufacturers and a push towards more sophisticated formwork solutions.

Types of Formwork Solutions

Concrete pillar formwork comes in various designs, tailored to specific project requirements. The most common types include

1. Traditional Timber Formwork Historically, timber was the go-to material for formwork. While still used in some regions, it has become less popular due to labor-intensive assembly and concerns about waste.

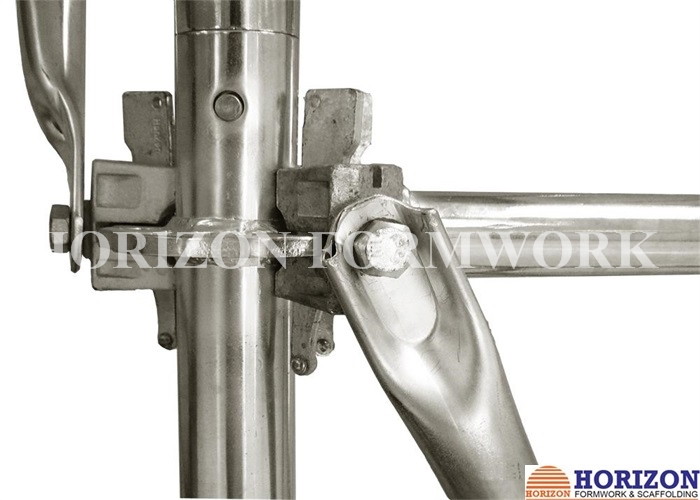

2. Steel Formwork Steel offers increased durability and can be reused multiple times, making it a cost-effective and eco-friendly option. Steel formwork can withstand the pressure and weight of wet concrete, providing a stable and reliable solution for larger projects.

3. Aluminum Formwork Lightweight and easy to handle, aluminum formwork is ideal for projects requiring a rapid turnaround. It allows for faster construction timelines and is reusable, which aligns with sustainability goals in modern construction.

concrete pillar formwork companies

4. Plastic Formwork This alternative is gaining traction due to its lightweight nature and resistance to weather conditions. Plastic formwork is particularly advantageous for complex pillar designs, as it can be molded into various shapes.

Innovations in Formwork Technology

In recent years, concrete pillar formwork companies have embraced cutting-edge technology to enhance their offerings. Digitalization and automation have significantly improved the precision of formwork manufacturing. Advanced software allows for the design of custom formwork solutions, optimized for specific project needs, thereby reducing waste and improving efficiency.

Moreover, some companies are exploring the use of modular formwork systems. These systems consist of standardized components that can be quickly assembled and adapted to various project dimensions. This flexibility not only speeds up the construction process but also allows for cost savings, as fewer unique materials are needed for different projects.

Sustainability in Formwork Production

As the construction industry becomes more aware of its environmental impact, concrete pillar formwork companies are adopting sustainable practices. This includes using recycled materials in formwork fabrication and minimizing waste during production. Furthermore, companies are exploring eco-friendly treatments for traditional materials like timber to enhance durability and reduce the need for chemical preservatives.

The push for sustainability is also evident in the design of formwork systems that can be reused multiple times before needing replacement. This not only reduces the environmental footprint but also offers long-term cost efficiency for construction firms.

Conclusion

Concrete pillar formwork companies are at the forefront of innovation in the construction industry. With a growing emphasis on quality, efficiency, and sustainability, these companies are adapting to meet the changing demands of modern construction. As technologies advance and sustainable practices become standard, the future of concrete pillar formwork looks promising. Builders and architects can look forward to enhanced solutions that not only improve structural integrity but also contribute to a more efficient and environmentally friendly construction process. As these trends continue to evolve, the role of formwork in the construction industry will undoubtedly expand, paving the way for even more innovative and resilient structures.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025