Nov . 28, 2024 00:37 Back to list

Top Exporters of Concrete and Steel Formwork Solutions for Construction Industry

The Role of Concrete and Steel Formwork Exporters in Global Construction

In the ever-evolving landscape of global construction, the demand for reliable and efficient building materials continues to rise. One critical component of modern construction practices is formwork, particularly concrete and steel formwork. As urbanization accelerates worldwide, the role of concrete and steel formwork exporters becomes increasingly significant, enabling infrastructure projects to progress smoothly and efficiently.

Understanding Formwork and Its Importance

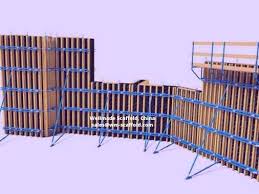

Formwork is a temporary or permanent mold into which concrete is poured to create structural elements such as walls, floors, and beams. It plays a crucial role in shaping and supporting concrete until it attains sufficient strength to bear loads independently. Various types of formwork exist, but concrete and steel formwork are particularly favored for their durability, strength, and adaptability.

Concrete formwork, often made from plywood, metal, or plastic, is designed for projects where shapes and sizes vary extensively. Conversely, steel formwork is preferred for large-scale projects due to its structural integrity and ability to reuse multiple times without compromising quality. The choice between concrete and steel formwork depends on various factors, including project scale, budget, and specific engineering requirements.

The Growing Demand for Concrete and Steel Formwork

The global construction industry is experiencing a renaissance, driven by rapid urbanization, increasing population density, and ongoing infrastructure development in emerging economies. As cities expand and evolve, the need for efficient construction methods has become paramount. This is where concrete and steel formwork exporters play a vital role.

Countries across Asia, Africa, and Latin America are investing heavily in infrastructure projects, from roads and bridges to residential and commercial buildings. This surge in demand presents a unique opportunity for exporters who can provide high-quality formwork solutions. With the construction sector evolving rapidly, exporters are expected to innovate and adapt their products to meet the ever-changing needs of the market.

Key Players in the Export Market

As the demand for concrete and steel formwork rises, several key players have emerged in the global marketplace. Exporters from countries with developed manufacturing capabilities, including Germany, Italy, and China, are at the forefront, offering a diverse range of formwork systems tailored to various construction needs.

concrete steel formwork exporters

These exporters invest heavily in research and development to improve the quality, safety, and efficiency of their products. Innovations such as lightweight formwork solutions, adjustable systems, and reusable materials reflect the industry's response to environmental concerns and cost-efficiency demands. By providing advanced formwork solutions, exporters contribute significantly to enhancing construction productivity and reducing waste.

Challenges Faced by Exporters

While the prospects for concrete and steel formwork exporters appear bright, several challenges must be navigated. Fluctuations in raw material prices, trade regulations, and logistical complexities can impact the export business. Moreover, the sustainability agenda within the construction sector poses a significant challenge, as companies must adapt their manufacturing processes and materials to reduce their carbon footprint.

In addition, fierce competition among exporters necessitates continuous innovation and exceptional customer service. Ensuring compliance with international standards and certifications is crucial for maintaining credibility and market presence, especially for exporters aiming to penetrate new markets.

Future Trends in the Formwork Export Industry

Looking ahead, several trends are anticipated to shape the concrete and steel formwork export industry. The integration of technology, such as Building Information Modeling (BIM) and smart construction solutions, is set to revolutionize formwork design and application. These advancements will enable exporters to offer tailored solutions that enhance project efficiency and minimize errors.

Furthermore, the ongoing emphasis on sustainability will drive demand for eco-friendly formwork materials and practices. Exporters who prioritize environmentally responsible manufacturing and promote sustainable practices are likely to gain a competitive edge in the market.

Conclusion

Concrete and steel formwork exporters are essential players in the global construction industry, facilitating the efficient execution of building projects worldwide. As the construction landscape continues to evolve, these exporters must adapt to changing demands, overcome challenges, and embrace innovative solutions. By doing so, they can ensure their continued relevance and contribute to the sustainable development of infrastructure in a rapidly urbanizing world.

-

Heavy Duty Tripod & Fork Head: Stable Camera Mount for Pro Shots

NewsJul.21,2025

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025