Nov . 23, 2024 18:53 Back to list

core wall formwork factories

Core Wall Formwork Factories Innovations in Construction

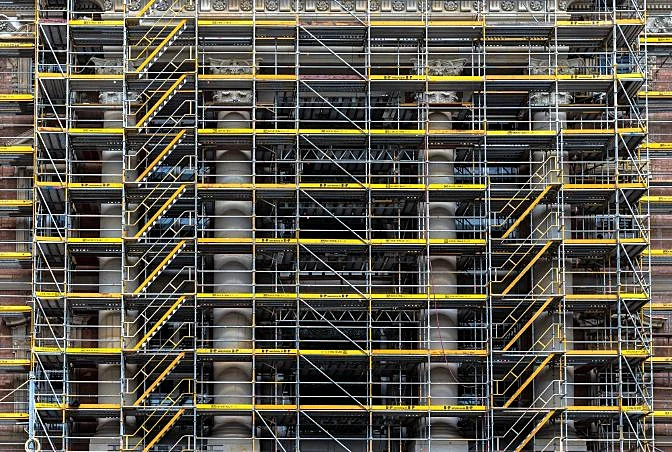

In the ever-evolving landscape of construction, core wall formwork has emerged as a critical component, contributing to the efficiency, safety, and sustainability of high-rise building projects. Core walls serve as the structural backbone of tall buildings, providing essential support for loads and enhancing overall stability. The demand for innovative core wall formwork solutions has prompted the rise of specialized factories that focus on producing these vital construction materials.

Core wall formwork factories are at the forefront of construction technology, employing advanced manufacturing techniques and state-of-the-art materials to create formwork systems that meet the rigorous demands of modern architecture. These factories utilize a range of materials, including steel, aluminum, and high-quality plywood, to produce formwork panels that are not only durable but also adaptable to various architectural designs.

One of the key advantages of modern core wall formwork systems is their modularity. Factories are now able to design and manufacture formwork components that can be easily assembled, disassembled, and reused. This modular approach significantly reduces waste and labor costs, as construction teams can quickly adapt to different site conditions and design changes. Furthermore, the lightweight nature of modern materials ensures that the installation process is efficient, allowing for quicker project completion timelines.

core wall formwork factories

Safety is another paramount consideration in the production of core wall formwork. Factories implement strict quality control measures and adhere to industry standards to produce formwork that can withstand the pressures of concrete pouring and the weight of additional building materials. Advanced engineering techniques allow for the design of formwork systems that are not only strong but also designed to minimize risks during installation and usage. These innovations lead to safer work environments and reduce the likelihood of accidents on construction sites.

Sustainability is increasingly becoming a focus within the construction industry, and core wall formwork factories are no exception. Many manufacturers are exploring eco-friendly materials and production methods to reduce their carbon footprints. Recyclable materials are being incorporated into formwork designs, and factories are optimizing their processes to reduce energy consumption. These sustainable practices not only benefit the environment but also align with the growing demand for green building initiatives.

Moreover, technology plays a significant role in the operations of core wall formwork factories. The integration of digital tools, such as Building Information Modeling (BIM) and automation, streamlines the design and manufacturing processes. Factories can utilize advanced software to create precise models, allowing for accurate projections of material requirements and costs. Automation in production processes enhances efficiency, enabling factories to meet the growing demands of the construction industry.

In conclusion, core wall formwork factories are revolutionizing the construction landscape by providing innovative, safe, and sustainable solutions for high-rise buildings. Their commitment to modular design, safety standards, and environmentally friendly practices positions them as essential players in the construction industry. As urbanization continues to rise, the role of these factories will become increasingly critical in shaping the skyline of the future, ensuring that our built environment is both resilient and reflective of modern architectural aspirations.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025