Aug . 12, 2024 16:04 Back to list

Deck Formwork Exporter for High-Quality Construction Solutions and Reliable Supply Chain Services

Deck Formwork Exporter Meeting Global Construction Needs

In the ever-evolving world of construction, the demand for innovative and efficient building solutions has led to an increased reliance on advanced materials and technologies. One such solution that has gained significant traction in modern construction is deck formwork. This temporary construction system plays a pivotal role in supporting concrete structures during the curing process, and its efficient design is crucial for the overall success of construction projects. As a result, the market for deck formwork exporters is flourishing, driven by both domestic and international demands.

Deck formwork systems comprise various components, including panels, props, and braces, all engineered to bear heavy loads. They are typically made from materials like steel, plywood, or aluminum, each offering distinct advantages tailored to specific construction needs. Steel formwork, for instance, is celebrated for its durability and reusability, making it a popular choice among contractors aiming to optimize their project budgets. On the other hand, aluminum formwork is prized for its lightweight nature and ease of handling, significantly reducing labor costs and construction time.

The expanding global construction market, especially in developing countries, is a significant factor propelling the growth of deck formwork exporters. Countries in Asia, Africa, and South America are experiencing rapid urbanization, which has led to a surge in high-rise buildings, bridges, and infrastructure projects. These developments necessitate robust formwork systems that can safely and efficiently support the demands of modern construction. Exporters who provide innovative deck formwork solutions are thus well-positioned to capitalize on this growing trend.

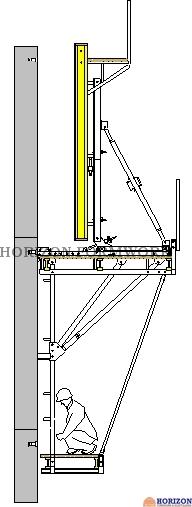

deck formwork exporter

Moreover, deck formwork exporters are increasingly adopting advanced technologies to enhance their products. For example, many manufacturers are now utilizing 3D modeling and Computer-Aided Design (CAD) to create customized formwork solutions that meet specific project requirements. This technological advancement allows for more precise manufacturing processes, leading to improved quality and reduced waste. Additionally, the incorporation of lightweight materials and modular designs helps in increasing efficiency and reducing handling times on the construction site.

Sustainability has also become a significant concern in the construction industry, which has prompted exporters to focus on eco-friendly products. By utilizing sustainable materials and promoting reusability, deck formwork exporters can meet the growing demand for environmentally responsible solutions. Initiatives such as recycling old formwork and investing in greener production methods are increasingly common among leading exporters, showcasing their commitment to sustainability.

In terms of market competition, deck formwork exporters face challenges from both local manufacturers and other international players. To remain competitive, exporters must continuously innovate, improve their product offerings, and ensure high standards of quality and safety. Building partnerships with construction companies and investing in robust logistics and supply chains can also enhance their market position.

In conclusion, the role of deck formwork exporters in the global construction landscape cannot be underestimated. With the ongoing demand for efficient, durable, and sustainable building solutions, these businesses play a crucial part in facilitating construction projects worldwide. As urbanization continues to rise and construction practices evolve, the future looks promising for deck formwork exporters who are willing to embrace innovation and adapt to market changes. By meeting the diverse needs of construction companies around the globe, they not only contribute to the industry's growth but also help shape the skylines of tomorrow.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025