Dec . 04, 2024 15:59 Back to list

Exporter of Drop Stripping Formwork Solutions for Efficient Construction Projects

Understanding the Importance of Drop Stripping Formwork in Construction A Look into Exporters

In the construction industry, the efficiency and quality of building processes are paramount. One crucial aspect that significantly contributes to the overall success of a project is the formwork system used during concrete pouring. Among various formwork techniques, drop stripping formwork has gained increasing attention, especially among exporters catering to international markets. This article delves into the features, benefits, and the role of exporters in promoting drop stripping formwork globally.

What is Drop Stripping Formwork?

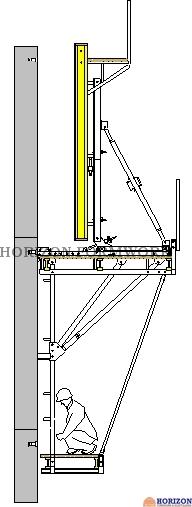

Drop stripping formwork is a type of system designed for concrete construction that simplifies the process of removing formwork after the concrete has cured. Unlike traditional methods that require multiple labor-intensive steps to dismantle the framework, drop stripping allows the panels to be easily stripped away, thus minimizing labor, time, and costs associated with formwork removal. This method is particularly advantageous in large-scale projects where efficiency is key to meeting construction deadlines.

Benefits of Drop Stripping Formwork

One of the primary advantages of using drop stripping formwork is the significant reduction in labor costs. The ease of removal minimizes the need for extensive manpower, allowing construction teams to reallocate resources to other tasks. Additionally, this method enhances the overall speed of construction projects. Quick stripping contributes to shorter project timelines, which is crucial for developers aiming to meet tight schedules.

Moreover, drop stripping formwork facilitates a cleaner worksite. Traditional formwork systems often leave debris and remnants that require cleanup after removal. In contrast, drop stripping systems are designed to minimize waste and simplify the cleanup process. This not only leads to a more organized job site but also improves safety for workers, as there is less clutter around.

drop stripping formwork exporter

The quality of the final product is another significant benefit. Drop stripping formwork systems are engineered to provide precise and consistent results. Smooth surfaces and uniform finishes are easier to achieve with top-quality materials and advanced construction techniques. As a result, the aesthetics of concrete structures are enhanced, which can be a selling point for developers in an increasingly competitive real estate market.

The Role of Exporters in the Global Market

The global demand for innovative construction solutions has led to a rise in exporters specializing in drop stripping formwork. These exporters play a vital role in bridging the gap between manufacturers and construction firms around the world. They not only provide access to high-quality formwork systems but also offer crucial insights into best practices, installation techniques, and maintenance.

By working closely with manufacturers, exporters ensure that the latest advancements in formwork technology are made available to clients. They also conduct market research to understand regional preferences and regulatory requirements, tailoring their offerings to suit various markets. This adaptability is essential for competing in a global landscape that varies widely in terms of construction practices and standards.

Furthermore, exporters often provide value-added services such as training and support. They assist construction teams in effectively implementing drop stripping formwork, ensuring that its benefits are fully realized. This educational component not only helps improve overall project outcomes but also fosters long-term relationships between exporters and their clients, leading to repeat business.

Conclusion

In conclusion, drop stripping formwork represents a significant advancement in construction technology. Its efficiency, cost-effectiveness, and quality benefits make it an appealing choice for modern building projects. With the support of dedicated exporters, this innovative formwork system is becoming increasingly accessible to construction businesses worldwide. As the industry continues to evolve, the importance of such export relationships will only grow, paving the way for more efficient and sustainable construction practices in the future.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025