Nov . 06, 2024 07:08 Back to list

engineered concrete formwork factory

Engineered Concrete Formwork Factory Revolutionizing Construction

The construction industry has witnessed monumental changes over the past few decades, primarily driven by advancements in technology and innovative engineering techniques. One of the most significant developments is the introduction of engineered concrete formwork, which has transformed the way concrete structures are built. This article explores the role of engineered concrete formwork factories in enhancing construction efficiency and quality.

Engineered Concrete Formwork Factory Revolutionizing Construction

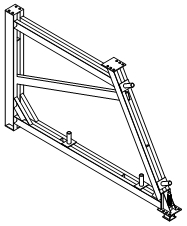

The rise of engineered concrete formwork factories has played a pivotal role in this transformation. These factories specialize in designing, manufacturing, and distributing formwork systems tailored to various construction projects. By leveraging advanced manufacturing techniques and rigorous quality control measures, these factories ensure that each formwork component meets the specific requirements of the construction industry.

engineered concrete formwork factory

One of the key advantages of engineered concrete formwork is its speed of installation. Traditional methods often involve time-consuming processes such as cutting and assembling wooden forms on-site. In contrast, formwork produced in specialized factories can be delivered pre-assembled or in modular components that can be quickly erected. This efficiency leads to reduced labor costs and shortened project timelines, enabling contractors to complete projects more swiftly and effectively.

Moreover, engineered formwork systems offer superior quality control. Factories employ automated production methods and stringent testing protocols to ensure each unit meets the required specifications. This consistency minimizes the risk of defects, resulting in a higher quality final product. For instance, the precise fit of engineered formwork reduces the chances of concrete leaks or blowouts, which can occur with poorly constructed wooden forms. This level of reliability is crucial for high-stakes projects such as bridges, skyscrapers, and infrastructure developments.

Sustainability is another factor driving the adoption of engineered concrete formwork. These systems are designed for multiple uses, significantly reducing waste compared to traditional formwork methods. Additionally, modern formwork materials are recyclable, further contributing to environmentally friendly construction practices. As the industry increasingly emphasizes sustainability, engineered formwork factories are positioned as leaders in producing eco-conscious solutions.

In conclusion, engineered concrete formwork factories are revolutionizing the construction landscape. By offering durable, efficient, and sustainable solutions, they help contractors deliver high-quality projects in a timely manner. As technology continues to evolve, the role of these factories will only become more critical in meeting the demands of an ever-changing construction industry. Embracing these advanced manufacturing techniques is essential for future developments, paving the way for innovations that will define the next generation of construction practices.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025