Dec . 23, 2024 12:12 Back to list

engineered formwork system supplier

Engineered Formwork System Suppliers Revolutionizing Construction

In the ever-evolving construction industry, the need for efficiency, precision, and sustainability is paramount. One of the most critical aspects of any construction project is the formwork system, which serves as the temporary mold that holds concrete until it sets. Engineered formwork systems have emerged as a pivotal solution, providing increased productivity, safety, and cost-effectiveness. This article explores the role of engineered formwork system suppliers in transforming construction practices.

What is Engineered Formwork System?

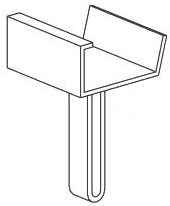

Engineered formwork systems are pre-designed, modular units manufactured from various materials such as steel, aluminum, or plastic. These systems can be tailored to meet specific project requirements, allowing for a high degree of versatility. Unlike traditional wooden formwork, engineered systems are designed to be reusable, durable, and easy to transport, making them a viable option for both large-scale and smaller construction endeavors.

Advantages of Engineered Formwork Systems

1. Cost-Effectiveness Although the initial investment in engineered formwork may be higher than traditional systems, the long-term savings are significant. These systems can be reused multiple times and require less labor for setup and dismantling, resulting in lower overall construction costs.

2. Quality and Precision Engineered formwork systems are meticulously designed, allowing for high precision in construction. This precision reduces the likelihood of errors and the need for costly rework, ensuring that projects are completed on schedule and within budget.

3. Safety Safety is a paramount concern on any construction site. Engineered formwork systems are designed to be structurally sound, reducing the risk of accidents associated with faulty or unstable formwork. Additionally, the lightweight materials used make handling easier and safer for workers.

engineered formwork system supplier

4. Sustainability In the context of increasing environmental awareness, engineered formwork systems are a sustainable choice. Their reusable nature minimizes waste, and many suppliers focus on environmentally friendly materials and manufacturing processes. This alignment with sustainability goals is attractive to contractors and clients alike.

5. Ease of Use Modern engineered formwork systems are designed for quick assembly and disassembly, enabling quicker project turnaround times. Many suppliers provide comprehensive training and support to ensure that construction teams can implement these systems efficiently.

The Role of Suppliers

Engineered formwork system suppliers play a vital role in the construction ecosystem. They are responsible for designing, manufacturing, and distributing these advanced systems. Suppliers not only provide the physical formwork but also offer technical support and expertise, helping contractors select the right system for their specific needs.

In addition, many suppliers are investing in research and development to innovate new products that cater to emerging construction techniques and materials. As construction demands shift towards more complex and high-tech solutions, suppliers that stay ahead of these trends are invaluable partners in the industry.

Conclusion

The integration of engineered formwork systems into construction projects marks a significant advancement in the field. Suppliers of these systems contribute to improved efficiency, enhanced safety, and reduced environmental impact in construction practices. As the industry continues to evolve, the role of engineered formwork suppliers will undoubtedly become even more crucial, driving innovations that will define the future of construction. For contractors looking to optimize their operations, investing in engineered formwork systems is no longer a question of “if,” but “when.” Embracing this transformative technology is essential for staying competitive in today’s fast-paced construction landscape.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025