Nov . 25, 2024 08:08 Back to list

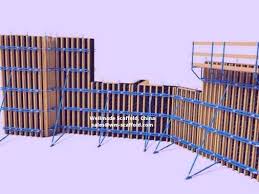

falsework for concrete manufacturer

Falsework for Concrete Manufacturing An Essential Guide

In the construction industry, the term 'falsework' refers to the temporary structures that support a permanent structure while it is being built. This critical component of construction is particularly vital in concrete manufacturing, where the integrity of the final structure relies heavily on the strength and precision of the temporary forms used during the setting and curing process. Understanding the importance of falsework in concrete construction can lead to enhanced safety, efficiency, and quality in building practices.

What is Falsework?

Falsework encompasses a range of structures, including frames, scaffolding, and other support systems that hold up molds and formwork necessary for shaping concrete until it achieves its designated strength. These temporary structures must be designed and assembled with precision to hold the weight of fresh concrete, which can be substantial, until the concrete hardens.

The Importance of Falsework in Concrete Manufacturing

1. Safety First Safety is paramount in any construction project. Falsework must be designed to withstand not only the weight of the wet concrete but also any dynamic loads that might occur from labor movements, equipment, or environmental factors, such as wind. Proper falsework ensures that the construction site is safe for workers and minimizes the risks of structural failure.

2. Precision and Quality Control The quality of concrete structures directly associates with the precision of the formwork used. Falsework plays a pivotal role in shaping and supporting concrete elements, ensuring that they meet design specifications. Any misalignment or failure in the falsework can lead to defects in the finished structure, which could have costly implications in terms of repairs and safety.

3. Efficiency and Cost-Effectiveness Efficient falsework systems allow for quicker construction timelines. Prefabricated falsework solutions can be assembled on-site quickly, reducing labor costs and expediting project completion. Additionally, using reusable falsework materials can significantly cut down on expenses associated with materials for each project.

4. Versatility Falsework is versatile and can be designed to accommodate various forms and structural needs. Whether constructing bridges, high-rise buildings, or other concrete structures, falsework systems can be customized to ensure that they meet the specific requirements of each project. This adaptability makes falsework an indispensable component of modern concrete construction.

Types of Falsework

falsework for concrete manufacturer

There are two main types of falsework commonly used in concrete manufacturing

1. Beam Falsework This type involves the use of beams and trusses to support horizontal loads. It is often used when constructing floors, bridges, and ceilings, providing a stable platform for placing concrete.

2. Shoring Systems These systems provide vertical support and are typically used in the initial stages of construction to support walls, columns, and other vertical elements. Shoring must be carefully calculated to handle both the live loads of construction activities and the dead loads of the cured concrete.

Design Considerations for Falsework

When planning for falsework, several factors must be taken into account

- Load-Bearing Capacity The falsework system must be able to carry the expected loads, including the weight of the concrete and any additional loads from construction activities.

- Material Durability Choosing the right materials for falsework is crucial. Temporary structures must not only support loads but also withstand weather conditions, moisture, and wear over time.

- Construction Sequence The timing and sequence of construction activities play a significant role in determining the design and installation of falsework. Efficient planning can minimize disruptions and maximize productivity.

Conclusion

Falsework is a critical aspect of concrete manufacturing that cannot be overlooked. Its primary functions—ensuring safety, maintaining precision, enhancing efficiency, and providing versatility—are essential for the successful completion of concrete structures. As construction technology continues to evolve, so too will the methods and materials used for falsework, leading to safer and more cost-effective practices in the industry. As such, understanding and investing in quality falsework systems should be a priority for manufacturers and builders alike, underscoring the foundation of modern construction.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025