Nov . 11, 2024 04:00 Back to list

Formwork Solutions for Beam and Slab Production in Construction Industry

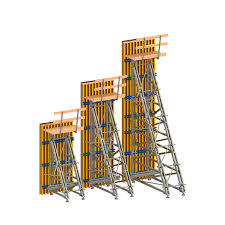

Formwork for Beam and Slab Factories An Essential Component for Efficient Construction

Formwork is a critical element in the construction industry, especially in the production of beams and slabs. Its primary purpose is to provide a temporary mold into which concrete is poured, ensuring that the structure achieves the desired shape and strength. In beam and slab factories, the use of effective formwork systems not only enhances the quality of concrete products but also significantly improves efficiency and reduces costs.

Types of Formwork

There are several types of formwork used in beam and slab manufacturing, each with its own set of advantages. The most common types include

1. Timber Formwork Traditionally, timber was the go-to material for formwork due to its availability and ease of use. However, it can be labor-intensive to set up and is not always the most durable option.

2. Steel Formwork Steel offers higher strength and durability compared to timber. It can withstand greater loads and can be reused multiple times, making it a cost-effective solution in the long run. This type of formwork is particularly beneficial for larger projects where consistent quality is essential.

3. Aluminium Formwork Emerging as a popular alternative, aluminum formwork is lightweight and easy to handle. Its high precision in manufacturing allows for tighter tolerances, resulting in a better finish for the concrete. Additionally, aluminum is highly resistant to corrosion, enhancing its lifespan.

4. Plastic Formwork This innovative material is gaining traction due to its lightweight nature and flexibility. Plastic formwork systems can be easily transported and set up, making them ideal for smaller projects or areas that require complex shapes.

formwork for beam and slab factories

Advantages of Modern Formwork Systems

The evolution of formwork technology has brought numerous advantages to beam and slab factories

- Speed of Construction Modern formwork systems are designed for quick assembly and disassembly, significantly speeding up the construction process. This efficiency helps meet project deadlines and lowers labor costs.

- Quality Control Using advanced formwork methods allows for greater control over the quality of the final product. Precise measurements and uniform surfaces lead to enhanced durability and fewer defects in beams and slabs.

- Safety Improved formwork systems minimize the risk of accidents on site. Their robust design ensures stability during the curing process, protecting workers and respecting safety regulations.

- Sustainability Many manufacturers have begun to focus on sustainability, employing formwork materials that can be recycled or reused. This shift not only reduces waste but also contributes to environmentally friendly construction practices.

Conclusion

Formwork plays a pivotal role in the efficiency and effectiveness of beam and slab factories. As the construction industry continues to evolve, the adoption of advanced formwork technologies will undoubtedly lead to better quality products and reduced costs. With an increasing emphasis on sustainability and safety, engineers and builders must stay updated on the latest developments in formwork solutions. Ultimately, investing in the right formwork will enhance operational efficiencies while ensuring that structural integrity is maintained, paving the way for innovative construction practices in the future.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025