Dec . 05, 2024 03:53 Back to list

Manufacturing Solutions for Concrete Column Formwork Systems and Techniques

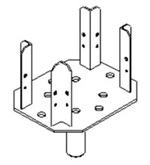

Formwork for Concrete Columns An Essential Component in Construction

Formwork plays a critical role in the construction industry, especially when it comes to creating strong and durable concrete columns. These structures are essential for a variety of buildings, from residential homes to skyscrapers, and they require precise and efficient formwork systems to ensure their integrity and stability. In this article, we will explore the importance of formwork for concrete columns, the various types of formwork available, and the benefits of using high-quality formwork from a factory.

The Importance of Formwork in Construction

Formwork serves as a mold for poured concrete, shaping it into the desired form before it cures and hardens. The quality and design of formwork are crucial for ensuring that concrete columns meet structural requirements and aesthetic expectations. Proper formwork not only helps in achieving the desired shape and size of columns but also influences factors like curing time, surface finish, and overall structural performance.

Concrete columns carry significant loads, providing support for the weight of beams, slabs, and the entire building structure. Therefore, the reliability and efficiency of formwork systems directly impact the safety and longevity of construction projects. Inadequate or poorly designed formwork can lead to defects, increased construction time, and even catastrophic failures.

Types of Formwork for Concrete Columns

There are various types of formwork available for concrete columns, each with its own set of advantages and applications.

1. Traditional Timber Formwork This is one of the oldest forms of formwork, made from plywood and lumber. While it is readily available and easy to work with, it can be time-consuming and less cost-effective for large-scale projects.

2. Steel Formwork This type is known for its durability and strength. Steel formwork can be reused multiple times and provides a high-quality surface finish. It is particularly suitable for large construction projects where consistency and efficiency are essential.

formwork for concrete columns factory

3. Aluminum Formwork Lightweight and easy to assemble, aluminum formwork is another popular choice. It offers faster installation and removal times while providing excellent concrete finishes. This type of formwork is widely used in residential and commercial buildings.

4. Plastic Formwork This modern solution is lightweight, reusable, and resistant to corrosion. Plastic formwork is ideal for complex shapes and provides good insulation properties, making it suitable for challenging weather conditions.

5. Precast Concrete Formwork This involves creating column sections off-site, which are then assembled on-site. Precast formwork can significantly reduce construction time and improve quality control.

Benefits of Using Factory-Made Formwork

Opting for factory-made formwork systems has several advantages. One significant benefit is consistency in quality; factory-produced formwork is manufactured under controlled conditions, ensuring precision and reliability. Furthermore, using factory-made systems can streamline the construction process, reducing labor time and minimizing waste. It also allows for customization according to specific project requirements, enhancing efficiency.

Additionally, factory-made formwork often comes with technical support and guidance, ensuring that construction teams can effectively utilize the system. This support is invaluable in ensuring that projects stay on schedule and within budget.

Conclusion

In conclusion, formwork for concrete columns is a fundamental aspect of successful construction projects. The choice of formwork type significantly impacts the quality, safety, and aesthetics of the final structure. Investing in high-quality, factory-made formwork systems not only enhances construction efficiency but also ensures that concrete columns are built to last, providing the necessary support for architectural vision and integrity. As the construction industry continues to evolve, embracing advanced and reliable formwork solutions will remain paramount in achieving excellence in building.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025