Oct . 11, 2024 17:23 Back to list

formwork for concrete wall suppliers

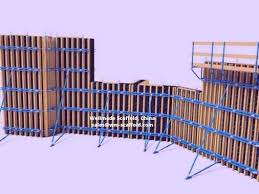

Understanding Formwork for Concrete Walls A Guide for Suppliers

Formwork is an essential component in the construction industry, particularly in the building of concrete walls. The process of formwork involves creating molds into which concrete is poured, allowing the material to take shape as it sets. Suppliers of formwork for concrete walls play a critical role in ensuring that construction projects run smoothly, effectively, and safely. This article explores the importance of formwork, different types available, and key considerations for suppliers.

Importance of Formwork

Formwork is crucial for a variety of reasons. First and foremost, it provides the shape and support necessary for concrete during the curing process. Without adequate formwork, concrete could collapse or deform, leading to structural failure and unsafe constructions. Additionally, proper formwork contributes to the overall efficiency of a construction project. It reduces the time required to pour concrete, promotes better quality finishes, and minimizes material waste.

Properly designed formwork also enhances safety on construction sites. When operators have reliable and robust formwork systems, the risk of accidents decreases significantly. As a supplier, understanding these critical roles of formwork enables you to communicate effectively with clients and provide them with the best solutions for their needs.

Types of Formwork

There are various types of formwork systems available, each suited for different applications and requirements

1. Timber Formwork Traditionally, timber has been the most commonly used material for formwork. It is versatile and can be easily cut to size, making it ideal for complex shapes. However, it can be less durable and requires more labor.

2. Steel Formwork Renowned for its strength and durability, steel formwork can be reused multiple times, making it a cost-effective option for large projects. It provides excellent surface finishes, decreasing the need for post-pouring finishing work.

3. Aluminum Formwork Similar to steel, aluminum formwork is lighter and easier to handle. It is also reusable and provides good quality finishes. Metals tend to have a longer life span compared to timber, but they can be more expensive.

formwork for concrete wall suppliers

4. Plastic Formwork This newer type of formwork is made from durable plastic materials. It is lightweight, easy to clean, and resistant to corrosion, making it a desirable option for many suppliers and contractors.

5. Permanent Formwork This type remains in place after the concrete is poured, providing added insulation and protection. It is particularly useful in constructing energy-efficient buildings.

Key Considerations for Suppliers

As suppliers of formwork for concrete walls, several key factors can help enhance your business and client satisfaction

- Quality Assurance Ensure that all formwork products meet industry standards and regulations. Offering high-quality materials will lead to better customer satisfaction and repeat business.

- Customization Be prepared to offer customized solutions, as each construction project has specific requirements based on design, timeline, and budget.

- Technical Support Providing technical assistance not only helps clients in choosing the right system but also in the effective assembly and use of the formwork.

- Education and Training Offering training sessions for contractors on the best practices for formwork installation can add significant value to your services.

In conclusion, formwork is a fundamental aspect of constructing concrete walls, and as a supplier, your role is vital in ensuring that construction projects are successful and meet the required safety and quality standards. Understanding the different forms of formwork and being attentive to client needs can position you as a key player in the construction supply industry.

-

Durable Powder Coating Steel Formwork Enhanced Lifespan & Protection

NewsJun.03,2025

-

Industrial High Load Scaffolding Suppliers Safe Heavy-Duty Solutions

NewsJun.03,2025

-

Prop 30-350 Premium Table Forms for Exporters & Suppliers

NewsJun.03,2025

-

Custom Falsework Systems for Construction Durable & Adjustable Solutions

NewsJun.03,2025

-

China Scaffolding Jacks - Durable & Adjustable Construction Solutions

NewsJun.03,2025

-

Euro Scaffolding Suppliers Durable & Custom Solutions

NewsJun.02,2025