Oct . 11, 2024 03:17 Back to list

Innovative Formwork Solutions for Efficient Wall Construction in Factories

Formwork for Wall Construction Factories A Comprehensive Overview

In the realm of construction, formwork is an essential component that significantly impacts the efficiency, safety, and quality of wall construction. Formwork serves as the mold that holds concrete in place while it cures, ensuring that walls achieve the desired shape and structural integrity. The use of formwork in wall construction factories has evolved dramatically, driven by technological advancements and innovative materials. This article delves into the various aspects of formwork for wall construction and its implications for modern construction practices.

Types of Formwork

There are several types of formwork used in wall construction, each with distinct advantages and applications. The most common forms include

1. Timber Formwork Traditionally, timber has been the go-to material for formwork due to its availability and ease of handling. However, it has limitations in terms of durability and reusability.

2. Steel Formwork Known for its strength and longevity, steel formwork can be reused numerous times, making it a cost-effective choice for large projects. It offers precise dimensions and great resistance to deformation.

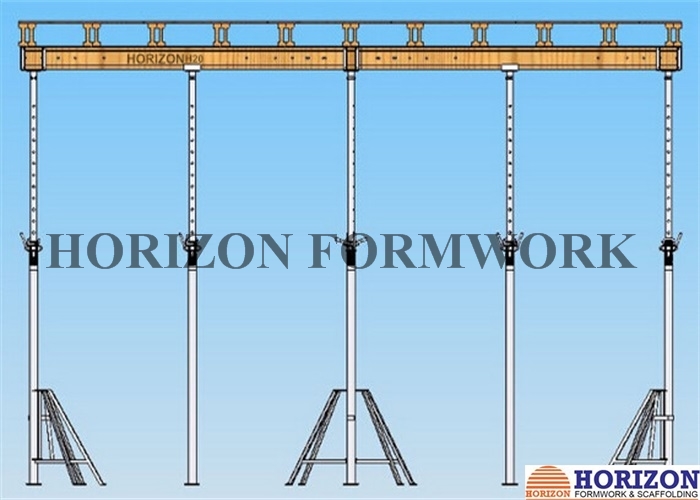

3. Aluminum Formwork Lightweight and durable, aluminum formwork is gaining popularity, particularly in residential and commercial buildings. Its flexibility in design allows for intricate wall shapes and structures.

4. Plastic Formwork This is a newer innovation in formwork technology. Plastic formwork is lightweight, easy to assemble, and resistant to water and chemicals, making it ideal for various environmental conditions.

Each type of formwork has its unique benefits and is chosen based on the specific requirements of the construction project.

Key Considerations for Formwork Design

When designing formwork for wall construction factories, several factors must be considered to ensure optimal performance

- Load-Bearing Capacity The formwork must withstand the weight of wet concrete and any equipment used during the pouring process.

formwork for wall construction factories

- Safety Standards Adequate safety measures must be in place to protect workers during the construction phase. This includes ensuring that the formwork is structurally sound and securely fastened.

- Time Efficiency The design should facilitate quick assembly and disassembly to minimize downtime and enhance productivity.

- Cost-Effectiveness Selecting materials and methods that balance durability and expense can lead to significant cost savings over the course of multiple projects.

Technological Innovations

The formwork industry is witnessing a wave of technological innovations that enhance its functionality and efficiency. Advanced software for structural analysis helps in designing more complex shapes without compromising safety. Moreover, the integration of modular and prefabricated systems allows for faster assembly and customization based on project needs.

Robotic systems are also being explored to automate the formwork installation process, reducing human error and improving overall productivity. These innovations not only streamline the construction process but also contribute to a significant reduction in labor costs.

Sustainable Practices

In today’s environmentally conscious world, sustainability in construction is paramount. The use of reusable formwork materials, such as steel and aluminum, reduces waste and the need for new resources. Additionally, manufacturers are increasingly focusing on eco-friendly materials for plastic formwork.

Moreover, innovations such as 3D-printed formwork are emerging as a sustainable alternative, allowing for intricate designs with minimal material waste. This approach aligns with the industry's goal of reducing its carbon footprint while maintaining high-quality construction standards.

Conclusion

Formwork plays a critical role in wall construction factories, affecting the efficiency, cost, and quality of building projects. As the construction industry continues to evolve, the advancement of formwork technology promises to enhance construction practices significantly. By understanding the various types of formwork, considering key design factors, and embracing innovative solutions and sustainable practices, the future of wall construction looks not only more efficient but also more responsible toward environmental stewardship.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025