Dec . 09, 2024 21:43 Back to list

Column Formwork Removal Timing for Construction Project Efficiency

Understanding Formwork Removal Time for Column Exporters

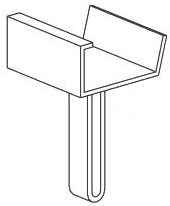

In the construction industry, the efficiency and timely execution of tasks play a significant role in determining the project’s overall success. One of the crucial aspects of this process is the formwork system, particularly when dealing with concrete columns. Formwork is a temporary structure used to support freshly poured concrete until it has attained sufficient strength. The removal of this formwork is a critical step, especially for exporters involving construction projects. This article delves into the various factors influencing formwork removal time for column exporters and the best practices to optimize this process.

Formwork removal time is influenced by several factors, including the type of concrete used, weather conditions, and the specifics of the construction project. The type of concrete mix is particularly significant; for instance, high-strength concrete can set faster, permitting earlier removal of the formwork. Conversely, if lower-strength concrete is used or if additives that slow down curing are included, the formwork may need to remain in place for a longer period.

Weather conditions also play a vital role. In warmer climates, concrete cures more quickly, allowing for reduced formwork removal time. On the other hand, colder temperatures may impede the curing process, necessitating extended periods before it is safe to remove the formwork. Rain or high humidity levels can also affect the curing rate and, by extension, the formwork removal timing.

Additionally, the design and complexity of the columns themselves can influence the removal schedule. For instance, intricate designs or columns with numerous embeds may require extra time for both curing and for ensuring the quality of the finish once the formwork is removed. Similarly, safety considerations play an integral role—ensuring that concrete has reached a specific compressive strength before formwork removal is essential to avoid compromising the structure’s integrity.

formwork removal time for column exporters

Optimizing formwork removal time begins with thorough planning. Exporters need to have a clear understanding of their concrete mix design and the associated curing times. Collaborating closely with suppliers and contractors can help streamline processes. Regular monitoring of weather forecasts can also provide valuable insights that impact the curing times, allowing for adjustments in scheduling as needed.

Technology has also made significant strides in improving formwork removal timelines. Advancements in curing compounds and equipment have minimized waiting times. For example, curing accelerators can reduce the time it takes for concrete to achieve the necessary strength for formwork removal. Additionally, the use of sensors to monitor the curing process provides real-time data, helping construction teams make informed decisions about when to proceed with formwork removal.

Moreover, proper training for workers involved in the formwork process is essential. Understanding the properties of concrete, identification of indications for readiness, and knowledge of along-term effects of early removal can heavily influence the efficiency and safety of the process. Investing in training ensures that all personnel understand the repercussions of premature or delayed formwork removal, thus reducing the likelihood of mistakes.

Communication is another critical aspect that can streamline formwork removal procedures. Keeping all team members informed about timelines and expectations ensures that everyone is aligned and can contribute to achieving the set goals effectively. This cooperative approach encourages problem-solving and adaptability in response to any unforeseen circumstances that may arise during the construction process.

In conclusion, the time taken for formwork removal in the context of column construction is a multifaceted issue influenced by various factors, including concrete type, weather, and the complexity of the design. Optimizing this process requires thorough planning, effective communication, implementation of innovative technologies, and continuous training. By addressing these elements, column exporters can enhance their efficiency, reduce project timelines, and ultimately, contribute to safer and more sustainable construction practices. As the industry continues to evolve, knowledge-sharing and collaboration will remain vital in achieving operational excellence in formwork removal.

-

Premium Formwork Wing Nuts & Tie Rods | Factory Supplier

NewsAug.29,2025

-

Expert Ringlock Scaffolding: Durable, Safe, Efficient Solutions

NewsAug.28,2025

-

Ringlock Scaffolding: Strong, Safe & Efficient Solutions

NewsAug.27,2025

-

OEM Column Formwork: Circular, Curved & Inclined Solutions

NewsAug.26,2025

-

Premium Scaffolding Jacks: Stable, Adjustable & Durable

NewsAug.25,2025

-

OEM Wall Formwork & Shuttering: Flexible & Curved Solutions

NewsAug.24,2025