Nov . 09, 2024 17:28 Back to list

Formwork Solutions for Tall Column Construction Companies

Innovative Formworks for High Columns Enhancing Construction Efficiency

In the modern landscape of construction, the need for innovation and efficiency is paramount, particularly when it comes to the erection of high columns. Formworks, which are temporary or permanent molds used to hold poured concrete in place, play a crucial role in shaping the structural integrity and aesthetics of buildings. As urban environments grow taller and more complex, the demand for advanced formworks specifically designed for high columns has surged. This article delves into the advancements in formwork technology and their significance to the construction industry.

High columns present unique challenges in construction, including issues related to weight-bearing capacity, stability, and the safe handling of materials. These challenges necessitate specialized formwork solutions that can support the significant dynamics of the construction process. Traditional formwork systems may not adequately address the issues posed by tall structures, leading to inefficiencies, increased labor costs, and heightened safety risks.

Innovative Formworks for High Columns Enhancing Construction Efficiency

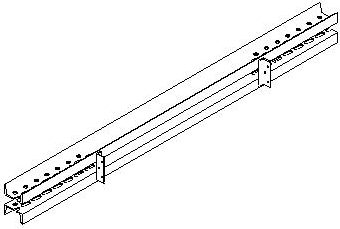

Moreover, modern formwork systems incorporate a variety of materials, including high-strength aluminum and fiberglass. These materials enhance durability and reduce the risk of deformation caused by heavy concrete pouring. For instance, aluminum formworks are particularly popular for their strength-to-weight ratio, allowing for higher loads without the need for excessive bracing or support. This not only maximizes efficiency but also streamlines the workflow on-site, enabling construction teams to focus on other critical tasks.

formworks for high columns company

The integration of technology, such as 3D modeling and computer-aided design (CAD), has revolutionized the way formworks are designed and executed. These tools facilitate precision in the design phase, enabling engineers and architects to simulate the structural behavior of high columns under various loads and conditions. When paired with advanced formwork systems, these designs can significantly enhance safety and reduce the likelihood of errors during construction.

Safety is an essential factor in any construction project, especially when dealing with high-rise structures. Innovative formwork systems are now equipped with advanced safety features, such as guardrails, anti-slip surfaces, and integrated scaffolding support. These enhancements not only protect workers but also minimize the risk of accidents that can occur during the placement of concrete. By prioritizing safety, construction companies can foster a culture of responsibility and care on-site, ultimately leading to a more efficient and productive workforce.

Another important aspect of modern formworks for high columns is their environmental sustainability. With growing awareness about the ecological impact of construction practices, many firms are opting for formwork solutions that utilize recycled materials and promote energy efficiency. Some systems are designed for reusability, allowing them to be used across multiple projects without significant degradation. This not only reduces material costs but also aligns with the broader goal of sustainable construction.

In conclusion, the evolution of formworks for high columns reflects a significant shift in the construction industry towards increased efficiency, safety, and sustainability. Innovations such as modular systems, advanced materials, and technological integration have transformed how high columns are constructed, addressing the unique challenges they pose. As urbanization continues to rise and the demand for taller structures grows, the importance of effective formwork solutions will only become more pronounced. By embracing these advancements, construction companies can ensure successful project execution, enhanced safety, and a positive impact on the environment. The future of high column construction is not only about reaching new heights but also about achieving greater efficiency and sustainability in the process.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025