Jan . 14, 2025 10:45 Back to list

formwork wing nut

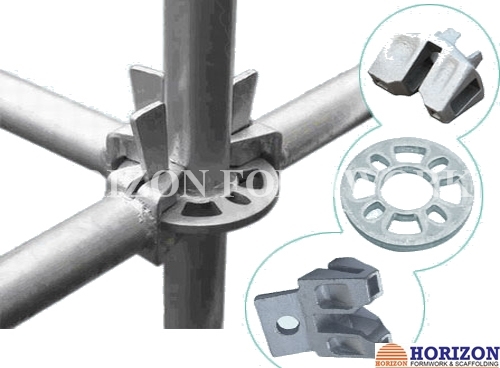

Selecting the right formwork wing nut is crucial in the construction industry for ensuring both the safety and effectiveness of building projects. The wing nut, although small, serves as a pivotal component in formwork systems, securing various elements in place during the concrete setting process. In today's competitive industry, understanding the nuances of different types of wing nuts, along with their applications, can provide substantial benefits to construction professionals who prioritize safety, efficiency, and durability.

With advancements in technology, some manufacturers have integrated intuitive features such as ergonomic designs or high-visibility color finishes that enhance safety on-site. High-visibility finishes help workers quickly spot components, reducing the likelihood of misplacement and accidental discard, thus improving workflow efficiency. Furthermore, understanding the different models available in the market enables the user to select the correct wing nut for specific projects. Wing nuts come in several forms, from economical lines catering to smaller projects, to heavy-duty versions tailored for high-pressure settings. Manufacturers provide detailed guidance and manuals, thereby reinforcing their commitment to authoritativeness and consumer trust. The expertise in usage extends beyond material and design to include understanding the correct assembly techniques. Properly installed wing nuts contribute to the structural coherence of formwork and prevent concrete leakage and misalignment, issues which could compromise the entire structure’s integrity. Installation guides and expert consultations from sellers serve as a valuable resource, offering insights to construction teams and fostering a culture of safety and efficiency. In essence, selecting a high-quality formwork wing nut founded on manufacture expertise and stringent quality standards is paramount for any construction endeavor. Comprehending the detailed aspects of these components not only cultivates a safer working environment but ensures the quality and longevity of the projects. With continuous developments and innovations, wing nuts stand as a testament to the blending of traditional engineering with modern efficiency and safety principles.

With advancements in technology, some manufacturers have integrated intuitive features such as ergonomic designs or high-visibility color finishes that enhance safety on-site. High-visibility finishes help workers quickly spot components, reducing the likelihood of misplacement and accidental discard, thus improving workflow efficiency. Furthermore, understanding the different models available in the market enables the user to select the correct wing nut for specific projects. Wing nuts come in several forms, from economical lines catering to smaller projects, to heavy-duty versions tailored for high-pressure settings. Manufacturers provide detailed guidance and manuals, thereby reinforcing their commitment to authoritativeness and consumer trust. The expertise in usage extends beyond material and design to include understanding the correct assembly techniques. Properly installed wing nuts contribute to the structural coherence of formwork and prevent concrete leakage and misalignment, issues which could compromise the entire structure’s integrity. Installation guides and expert consultations from sellers serve as a valuable resource, offering insights to construction teams and fostering a culture of safety and efficiency. In essence, selecting a high-quality formwork wing nut founded on manufacture expertise and stringent quality standards is paramount for any construction endeavor. Comprehending the detailed aspects of these components not only cultivates a safer working environment but ensures the quality and longevity of the projects. With continuous developments and innovations, wing nuts stand as a testament to the blending of traditional engineering with modern efficiency and safety principles.

Latest news

-

Premium H20 Timber Beams | Durable Structural Solutions

NewsAug.05,2025

-

Premium Wall Formwork Solutions for Modern Construction

NewsAug.03,2025

-

China Single Sided Wall Formwork: AI-Optimized Solutions

NewsAug.02,2025

-

Premium Timber Beam H20 | Strong & Durable Construction

NewsJul.31,2025

-

China Single-Sided Wall Formwork: High-Efficiency Design

NewsJul.31,2025

-

High-Quality Wall Formwork Systems for Versatile Concrete Construction

NewsJul.30,2025