Nov . 04, 2024 17:12 Back to list

Metal Formwork Solutions for Foundation Construction Companies and Projects

The Role of Metal Formwork Companies in Foundation Construction

In the construction industry, the foundation is one of the most critical components of any structure. It is the base that supports the entire building and ensures stability and longevity. To achieve a strong and durable foundation, builders rely on advanced techniques and materials, among which metal formwork has gained significant traction. Metal formwork companies play a crucial role in this process, providing innovative solutions that enhance the efficiency and quality of foundation construction.

What is Metal Formwork?

Metal formwork refers to a system of molds made from materials like steel or aluminum, used to shape and support concrete during its curing process. Unlike traditional wooden forms, metal forms offer greater durability, reusability, and precision. They can withstand the harsh conditions of construction sites, making them an ideal choice for large-scale projects, including high-rise buildings and commercial complexes. The use of metal formwork not only improves the structural integrity of foundations but also expedites the construction timeline, which is a significant advantage in today's fast-paced construction environment.

Benefits of Using Metal Formwork

One of the primary advantages of metal formwork is its reusability. High-quality metal forms can be used multiple times without significant degradation, leading to reduced material costs in the long run. Additionally, the lightweight nature of aluminum forms makes them easier to handle and install, which can lead to savings in labor costs and time.

Moreover, metal formwork systems are designed with precision, allowing for consistent and uniform results. This accuracy leads to a better fit for reinforcement bars and other structural elements, which is crucial for the overall strength of the foundation. The smooth surfaces of metal formwork also result in a clean finish, reducing the need for extensive post-construction treatments like plastering.

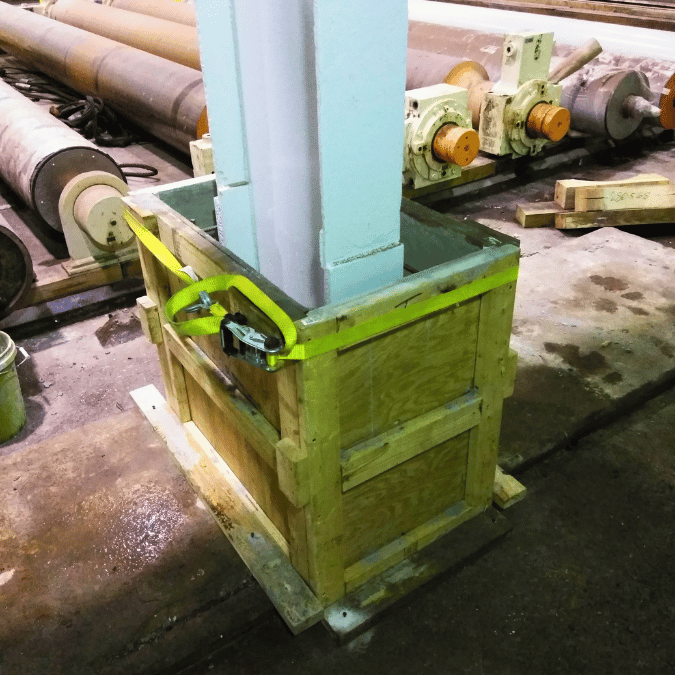

foundation formwork metal companies

Innovation in Metal Formwork

The industry has seen numerous innovations in metal formwork technology in recent years. Companies are continually developing new products and techniques that enhance the overall construction process. For example, some modern systems incorporate modular designs, allowing for quick assembly and disassembly. This can significantly cut down on the time required to set up formwork, enabling faster project completion.

Additionally, advancements in computer-aided design (CAD) technology have allowed formwork companies to provide customized solutions tailored to specific project needs. This level of customization ensures that the unique challenges of each construction site are addressed, leading to more effective and efficient use of resources.

The Future of Metal Formwork in Foundation Construction

As the construction industry moves toward sustainable practices, metal formwork companies are also adapting. The push for eco-friendly building materials has led some manufacturers to develop systems that minimize waste and carbon footprint. Additionally, the integration of smart technologies, such as sensors that monitor the curing process of concrete, is becoming more common, further enhancing the efficiency and safety of construction operations.

In conclusion, metal formwork companies play an essential role in foundation construction. Their innovative solutions provide builders with the tools needed to create robust and reliable foundations while also promoting efficiency and sustainability. As technology continues to evolve, it is likely that the impact of metal formwork on the construction industry will only grow, shaping the future of building practices for years to come. For contractors, architects, and developers, partnering with a reputable metal formwork company is an investment in quality and longevity, ensuring that foundations are not only strong but also built for the future.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025