Nov . 22, 2024 00:51 Back to list

h20 timber beam for shuttering supplier

H20 Timber Beams for Shuttering An Essential Component for Construction

In the construction industry, efficient and reliable materials are crucial for ensuring the integrity and durability of structures. One such material that has gained significant popularity is the H20 timber beam, particularly in shuttering applications. Known for its remarkable strength-to-weight ratio, H20 beams have revolutionized formwork systems, offering a solution that combines performance, safety, and cost-effectiveness.

Understanding H20 Timber Beams

H20 timber beams are engineered wooden beams characterized by their H shape, which contributes to their robustness and lightweight nature. Typically made from laminated veneer lumber (LVL), these beams undergo a meticulous manufacturing process that enhances their load-bearing capabilities while minimizing warping and shrinkage. This engineering makes them ideal for use in formwork systems for casting concrete.

Advantages of Using H20 Timber Beams

1. Lightweight Structure One of the most significant benefits of H20 beams is their lightweight design, which facilitates easier handling and transportation on construction sites. Workers can maneuver these beams without the need for heavy lifting equipment, enhancing overall operational efficiency.

2. High Load-Bearing Capacity H20 beams boast impressive load-bearing capabilities, making them suitable for a variety of applications, including horizontal shutters for slabs and vertical supports for wall forms. Their strength allows them to support substantial weights without compromising the quality of construction.

3. Versatility in Application H20 timber beams can be easily adapted to various formwork systems, accommodating different shapes and sizes. Whether for slabs, walls, or columns, these beams provide flexibility that can be tailored to meet specific project requirements.

4. Cost-Effectiveness Although the initial investment in H20 beams may be slightly higher compared to traditional timber, their durability and longevity lead to cost savings in the long run. Reduced labor costs, thanks to their lightweight and easy assembly, further enhance their economic viability.

h20 timber beam for shuttering supplier

5. Eco-Friendly Alternative Using engineered timber like H20 beams reduces the demand for solid wood, promoting sustainable forestry. Moreover, with increasing emphasis on environmentally responsible building practices, H20 beams align well with eco-friendly construction goals.

Application in Shuttering Systems

In the context of shuttering, H20 timber beams serve as the backbone of formwork solutions. They support plywood panels, which are used to shape and contain poured concrete until it hardens. The structural integrity provided by H20 beams ensures that the formwork remains stable, preventing any premature deformation or collapse during the curing process.

Moreover, the dimensional accuracy of H20 beams guarantees a high-quality finish for the concrete surfaces. This accuracy minimizes the need for extensive finishing work post-curing, thus streamlining the construction timeline and reducing overall costs.

Supplier Considerations

When sourcing H20 timber beams for shuttering applications, it is essential to collaborate with reputable suppliers. A reliable supplier ensures that the beams meet rigorous quality standards and certification requirements. Additionally, consider suppliers who can provide technical support, including installation guidelines and strength calculations, to assist in maximizing the beams' performance on-site.

Furthermore, establishing a long-term relationship with a timber beam supplier can lead to bulk purchase discounts, consistent supply chains, and improved service delivery.

Conclusion

H20 timber beams represent a pivotal advancement in the construction industry, especially for shuttering applications. Their lightweight nature, high load-bearing capacity, versatility, and cost-effectiveness make them a superior choice for modern construction projects. As the industry continues to evolve, embracing innovative materials such as H20 beams will be essential in achieving efficiency, sustainability, and excellence in structural integrity. Investing in quality H20 timber beams from trusted suppliers not only enhances project outcomes but also supports sustainable building practices that are crucial for the environment and future generations.

-

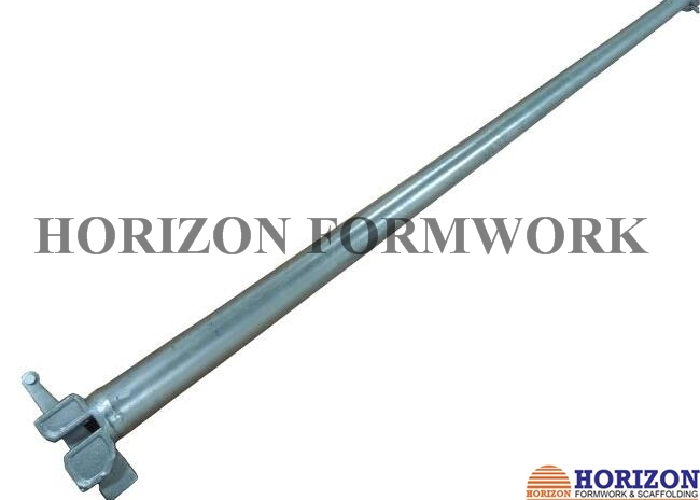

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025