Nov . 12, 2024 05:26 Back to list

industrial scaffolding tools factory

The Essential Role of Industrial Scaffolding Tools in Construction

In the world of construction, ensuring safety, efficiency, and productivity is of paramount importance. One of the key components that contribute to these factors is industrial scaffolding tools. As construction projects become increasingly complex and demanding, the need for robust and reliable scaffolding solutions has never been more critical. This article explores the significance of industrial scaffolding tools, their various types, and the essential safety measures that must be in place at a scaffolding tools factory.

Understanding Scaffolding Tools

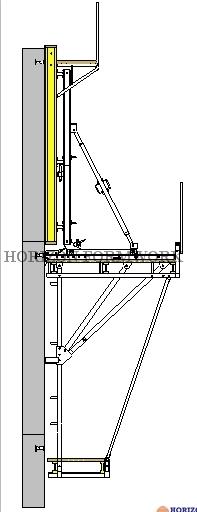

Scaffolding tools serve as temporary structures that provide support and access to workers and materials during construction or maintenance activities. They are crucial in reaching elevated areas, enabling workers to perform tasks safely and efficiently. Common types of scaffolding include supported scaffolds, suspended scaffolds, rolling scaffolds, and aerial lifts. Each type serves different purposes, depending on the specific requirements of a project.

1. Supported Scaffolds These are the most common type, consisting of platforms supported by rigid, load-bearing structures. They provide a stable working surface for workers and materials, making them suitable for various tasks.

2. Suspended Scaffolds Often used for tasks such as window cleaning or building maintenance, suspended scaffolds are platforms that are hung from an overhead structure. They require careful handling and are equipped with safety measures to prevent accidents.

3. Rolling Scaffolds These mobile scaffolds are ideal for projects that require movement within a site. They are equipped with wheels, allowing workers to reposition the scaffold easily without the need for disassembly.

4. Aerial Lifts Aerial lifts are specialized equipment that provides elevated access to various working heights. They are commonly used in construction, maintenance, and installation work, offering flexibility and mobility.

The Manufacturing Process in Scaffolding Tools Factory

The manufacturing of scaffolding tools is a meticulous process that requires adherence to strict safety and quality standards. A scaffolding tools factory typically involves several key steps

1. Material Selection The choice of materials is crucial in ensuring the durability and strength of the scaffolding tools. High-quality steel or aluminum is commonly used due to its strength-to-weight ratio.

industrial scaffolding tools factory

2. Design and Engineering Scaffolding tools must meet specific load-bearing requirements and adhere to industry standards. Engineers design these tools to optimize functionality while ensuring safety.

3. Production and Fabrication The fabrication process involves cutting, welding, and assembling the components of scaffolding tools. Advanced machinery and skilled labor are essential to produce tools that meet the required specifications.

4. Quality Control Rigorous quality control measures are implemented to ensure that all products meet safety standards. This includes tensile testing, load testing, and inspections to identify any defects.

5. Final Testing and Certification Before the scaffolding tools are shipped to customers, they undergo final testing to validate their safety and performance. Certifications from relevant authorities add assurance of compliance with industry regulations.

Safety Considerations in Scaffolding

Safety is a fundamental concern in the construction industry, particularly when it comes to the use of scaffolding tools. A scaffolding tools factory must prioritize safety in every aspect of its operations. This involves

1. Employee Training Workers in the factory must receive comprehensive training on the proper use and handling of scaffolding materials. Understanding safety protocols can significantly reduce the risk of accidents.

2. Regular Inspections Scaffolding equipment must be regularly inspected for wear and tear. Any damaged parts should be promptly replaced to maintain safety standards.

3. Compliance with Regulations Adherence to local and international safety regulations is essential. Scaffolding tools should be designed and manufactured in compliance with these standards to ensure worker safety.

Conclusion

Industrial scaffolding tools are an integral part of the construction industry, providing essential support and access to workers undertaking complex projects. The manufacturing process in a scaffolding tools factory is a blend of engineering, safety, and quality control, ensuring that the final products are reliable and efficient. By prioritizing safety and adhering to regulations, scaffolding tools contribute to safer working conditions and enhanced productivity in the construction field. As construction demands continue to evolve, the importance of these tools will undoubtedly grow, reinforcing their role as a cornerstone of safe and efficient construction practices.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025