Oct . 12, 2024 16:03 Back to list

industrial scaffolding tools manufacturers

The Role of Industrial Scaffolding Tools Manufacturers

Industrial scaffolding tools manufacturers play a crucial role in the construction and renovation sectors by providing essential equipment that ensures worker safety and efficiency at elevated heights. Scaffolding systems are temporary structures that support a work crew and materials, allowing for safe access to hard-to-reach areas. As construction projects continue to grow in scale and complexity, the demand for high-quality scaffolding tools has never been higher.

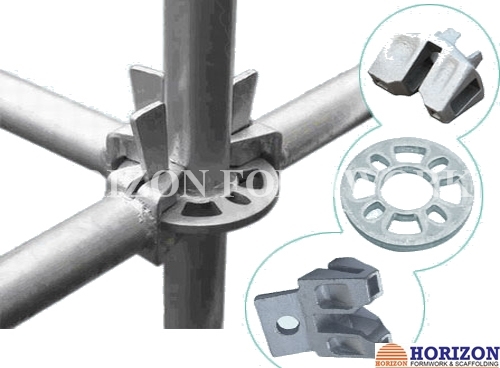

Manufacturers of scaffolding tools are tasked with creating a wide array of products, including scaffolding frames, planks, brackets, and couplers. These tools are engineered to meet stringent safety standards while also providing ease of use. The materials used in scaffolding production typically include steel and aluminum due to their durability and strength. Steel scaffolding is known for its robustness, making it ideal for heavy-duty applications, whereas aluminum scaffolding is lighter and easier to maneuver, suitable for smaller projects.

In an era where safety is paramount, these manufacturers invest heavily in research and development to improve their products continuously. Advanced engineering techniques and rigorous testing methodologies ensure that scaffolding tools not only meet regulatory requirements but also withstand the rigors of daily use on construction sites. These improvements help to minimize the risk of accidents, which can lead to costly delays and injuries.

industrial scaffolding tools manufacturers

Moreover, the market is seeing a shift towards modular scaffolding systems. These systems offer flexibility and adaptability, allowing construction teams to configure the scaffolding to meet the unique demands of each project. Manufacturers are responding to this trend by incorporating innovative designs that make installation and dismantling faster and more efficient. This shift not only reduces labor costs but also improves project timelines, further enhancing productivity on construction sites.

Another critical aspect that scaffolding tools manufacturers focus on is sustainability. With an increasing emphasis on eco-friendly practices, many manufacturers are exploring the use of recycled materials and more sustainable production methods. This commitment helps to minimize their environmental impact while meeting the growing demand for green building practices in the industry.

In conclusion, industrial scaffolding tools manufacturers are essential contributors to the construction industry's safety and efficiency. Their commitment to innovation, quality, and sustainability ensures that construction projects can proceed effectively while prioritizing the well-being of workers. As the industry continues to evolve, manufacturers will play an increasingly significant role in providing the scaffolding solutions needed for the future of construction. Through continuous improvement and adaptation, they not only meet the current demands but also anticipate future trends, reinforcing their position as vital players in the construction landscape.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025