Dec . 06, 2024 22:06 Back to list

Lightweight Scaffolding Solutions for Modern Construction Needs

The Rise of Light Scaffolding Factories A Sustainable Future for Construction

In an age where sustainability and efficiency are paramount, the construction industry is undergoing a significant transformation. At the forefront of this revolution are light scaffolding factories, which are reshaping the way we think about scaffolding systems. These innovative facilities produce lightweight scaffolding solutions that are not only easy to transport and assemble but also contribute to a greener construction ecosystem.

Understanding Light Scaffolding

Light scaffolding systems are designed to be robust yet lightweight, allowing for easier handling and reduced transportation costs. These scaffolding structures are typically made from high-strength materials such as aluminum or advanced composites that offer both structural integrity and weight advantages. This makes them ideal for a wide range of applications, from small residential projects to large-scale commercial constructions.

The primary advantage of light scaffolding is its portability. Traditional scaffolding can be cumbersome and heavy, often requiring numerous workers to install and dismantle. In contrast, lightweight scaffolding can be assembled quickly by fewer workers, leading to significant reductions in labor costs and project timelines. Moreover, their ease of use minimizes the risks associated with lifting and handling heavy materials on job sites.

The Role of Factories in Production

Light scaffolding factories play a crucial role in this innovation. By adopting cutting-edge manufacturing techniques, these factories can produce scaffolding components that meet the highest standards of safety and efficiency. Advanced technologies such as computer numerical control (CNC) machining and automated welding processes allow for precision fabrication, resulting in scaffolding systems that are both strong and lightweight.

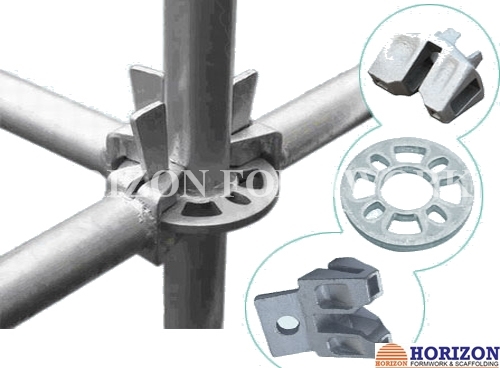

light scaffolding factory

Furthermore, many light scaffolding factories are embracing sustainable practices. This includes sourcing materials from environmentally friendly suppliers, utilizing recycling programs for scrap materials, and employing energy-efficient methods in their production processes. Such efforts not only reduce the ecological footprint of scaffolding manufacturing but also align with the global push towards sustainability in construction.

Impact on the Construction Industry

The introduction of light scaffolding systems is having a profound impact on the construction industry. As projects seek to minimize time and costs while maximizing safety, these scaffolding solutions have emerged as the preferred choice for many contractors. Their lightweight nature reduces the need for heavy machinery, resulting in lower site preparation costs and diminished impact on the surrounding environment.

Additionally, the agility that light scaffolding brings to project management allows for greater flexibility on job sites. Contractors can quickly adapt to changes in design or schedules, moving and reconfiguring scaffolding systems as needed. This responsiveness is invaluable in today’s fast-paced construction environment, where delays can lead to increased expenses and lost opportunities.

Looking Forward

As light scaffolding factories continue to expand and innovate, the future of scaffolding in construction appears bright. With advancements in materials science and manufacturing techniques, we can expect even more efficient and sustainable solutions to emerge. These developments not only serve the needs of contractors but also contribute to an industry-wide shift towards greener practices.

In conclusion, the emergence of light scaffolding factories signifies a pivotal moment for the construction industry. By prioritizing efficiency, safety, and sustainability, these facilities are setting new standards for scaffolding production. With the ongoing demand for innovative building solutions, light scaffolding is poised to become an integral part of the construction landscape, paving the way for a more sustainable and efficient future. As we move forward, embracing these advanced systems will be essential for addressing the challenges that lie ahead in the ever-evolving realm of construction.

-

Adjustable Heavy Duty Props for Slab Formwork - Max Load & Safety

NewsAug.30,2025

-

Premium Formwork Wing Nuts & Tie Rods | Factory Supplier

NewsAug.29,2025

-

Expert Ringlock Scaffolding: Durable, Safe, Efficient Solutions

NewsAug.28,2025

-

Ringlock Scaffolding: Strong, Safe & Efficient Solutions

NewsAug.27,2025

-

OEM Column Formwork: Circular, Curved & Inclined Solutions

NewsAug.26,2025

-

Premium Scaffolding Jacks: Stable, Adjustable & Durable

NewsAug.25,2025