Oct . 01, 2024 12:26 Back to list

lightweight scaffolding production facility for efficient construction solutions

The Rise of Lightweight Scaffolding Factories

In recent years, the construction industry has witnessed significant transformations powered by innovation and a growing emphasis on efficiency and safety. One of the most prominent trends emerging from this evolution is the rise of lightweight scaffolding factories. These facilities produce advanced scaffolding solutions that not only enhance structural support but also prioritize mobility, ease of assembly, and overall safety for workers on site.

Understanding Lightweight Scaffolding

Lightweight scaffolding refers to scaffolding systems designed using materials that reduce the overall weight without compromising strength and stability. Historically, scaffolding was constructed from heavy steel, which provided durability but added challenges in terms of transport and assembly. The introduction of materials like aluminum and advanced composites has revolutionized scaffolding design, making it possible to create robust structures that are significantly lighter.

The benefits of lightweight scaffolding extend beyond mere transportation. These systems are easier to install and dismantle, which saves valuable time on construction sites. With quicker setup times, projects can proceed more efficiently, ultimately reducing labor costs. Moreover, the lightweight nature of these materials does not detract from their strength. Modern testing has shown that many lightweight solutions can support the same loads as their heavier counterparts.

The Role of Factories in Innovation

The lightweight scaffolding factory plays a central role in the development and distribution of these advanced products. These factories are pivotal hubs of innovation, often equipped with the latest technology for manufacturing and design. By investing in state-of-the-art machinery and employing skilled labor, these factories are able to produce scaffolding solutions that meet the rigorous demands of the construction industry while adhering to safety standards.

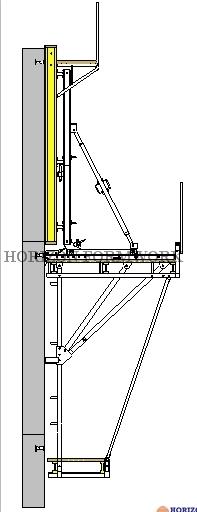

light weight scaffolding factory

Additionally, lightweight scaffolding factories tend to be more environmentally conscious compared to traditional scaffolding manufacturers. The use of sustainable practices and recyclable materials has become a standard operating procedure in many such facilities. As the construction industry shifts towards greener practices, these factories are leading the way by producing scaffolding products that align with sustainable building practices.

Safety and Compliance

Safety remains a paramount concern in the construction sector, and the lightweight scaffolding factory has adapted to meet this challenge. Lightweight scaffolding systems often feature enhanced safety components, including non-slip surfaces and integrated guardrails. Factories are continuously testing their products to satisfy both local and international safety regulations, thereby ensuring that their scaffolding can withstand the rigors of everyday use.

Furthermore, lighter scaffolding contributes to improved worker safety. Traditional scaffolding can pose significant risks during assembly and disassembly due to its weight. With lightweight options, workers can maneuver parts with greater ease and less physical strain. Factories are also focusing on providing comprehensive training programs, ensuring that workers are knowledgeable about the proper use and setup of these lightweight systems, thus further mitigating risks on site.

Market Expansion and Future Outlook

The demand for lightweight scaffolding is projected to grow as more construction firms recognize the advantages these systems provide. As urbanization continues to increase globally, the need for efficient construction solutions that ensure worker safety is more crucial than ever. Consequently, lightweight scaffolding factories are likely to expand their production capabilities, explore international markets, and invest in research and development to create even more innovative scaffolding solutions.

In conclusion, the emergence of lightweight scaffolding factories represents a significant shift in the construction industry's approach to scaffolding. By prioritizing lightness, safety, and efficiency, these factories not only enhance the workflow on construction sites but also contribute to the industry's overall sustainability goals. As technology progresses and more companies embrace these advanced solutions, the future of scaffolding looks promising, paving the way for safer, more efficient construction practices worldwide.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025