Jun . 26, 2024 10:17 Back to list

Metal Scaffoldings Factory Direct Prices for High-Quality Solutions

Understanding the Nuances of Metal Scaffold Pricing from Leading Factories

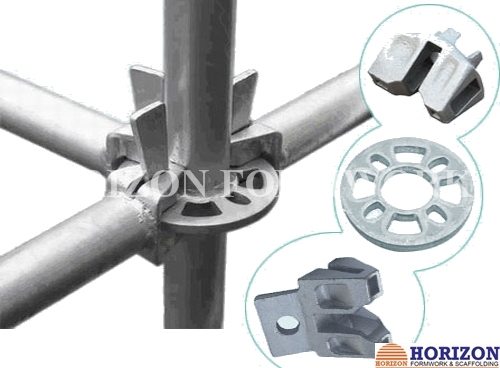

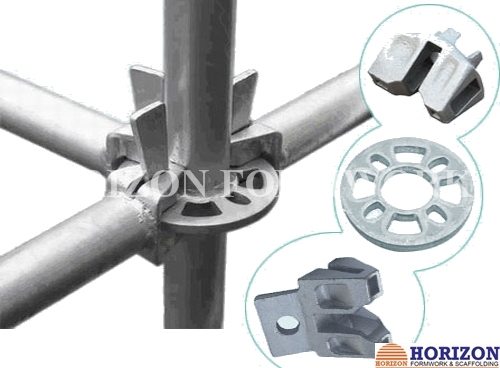

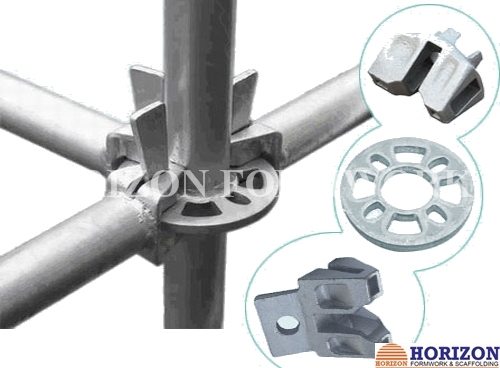

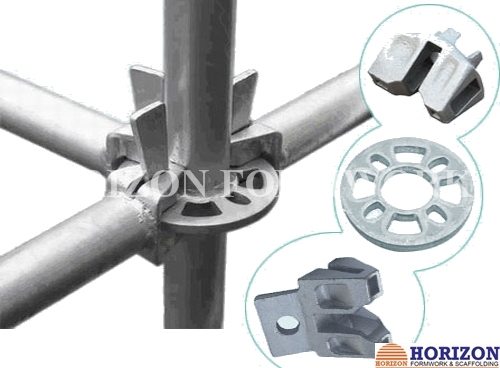

In the realm of construction and engineering, metal scaffolding plays an indispensable role, providing a sturdy and reliable platform for workers to execute their tasks safely and efficiently. The price of metal scaffolding is not just a simple figure but a complex interplay of various factors, influenced significantly by the manufacturing factories that produce them.

Metal scaffolding, typically made from high-strength steel, is designed to withstand harsh conditions and heavy loads. The pricing of these structures is primarily determined by the quality of materials used, production process, design complexity, and factory's operational costs.

Firstly, the quality of the metal determines the overall durability and safety of the scaffolding. High-grade steel, while more expensive, ensures greater stability and resistance to corrosion, making it a preferred choice in the industry. Thus, factories that use premium materials will naturally quote higher prices.

Secondly, the production process, whether automated or manual, affects the cost. Advanced machinery and technology can increase efficiency and reduce labor costs, which may reflect in the pricing. However, some factories might maintain a balance between automation and manual labor to maintain quality while keeping costs competitive.

Design complexity is another significant factor. Customized designs, while meeting specific project requirements, often entail additional engineering and manufacturing costs Customized designs, while meeting specific project requirements, often entail additional engineering and manufacturing costs Customized designs, while meeting specific project requirements, often entail additional engineering and manufacturing costs Customized designs, while meeting specific project requirements, often entail additional engineering and manufacturing costs

Customized designs, while meeting specific project requirements, often entail additional engineering and manufacturing costs Customized designs, while meeting specific project requirements, often entail additional engineering and manufacturing costs metal scaffolding price factory. This could lead to a higher price point compared to standard, off-the-shelf models.

Operational costs, including overheads, transportation, and after-sales services, also contribute to the final price. A factory with a wide distribution network and comprehensive customer support might charge slightly more to cover these expenses.

When considering metal scaffolding prices from different factories, it's crucial to weigh not only the upfront cost but also the long-term benefits. A slightly higher-priced product from a reputable factory, known for its quality and service, might prove to be a more cost-effective solution in the end.

Furthermore, market dynamics, such as supply and demand, global steel prices, and currency fluctuations, can impact the pricing. It's advisable to keep an eye on these trends and engage in open communication with the factory to negotiate the best deal.

In conclusion, understanding the factors influencing metal scaffolding prices from factories is vital for making informed purchasing decisions. It's about striking a balance between cost, quality, and service, ensuring that the chosen scaffolding meets both project requirements and budget constraints. Remember, investing in robust and reliable scaffolding is an investment in safety and project efficiency.

metal scaffolding price factory. This could lead to a higher price point compared to standard, off-the-shelf models.

Operational costs, including overheads, transportation, and after-sales services, also contribute to the final price. A factory with a wide distribution network and comprehensive customer support might charge slightly more to cover these expenses.

When considering metal scaffolding prices from different factories, it's crucial to weigh not only the upfront cost but also the long-term benefits. A slightly higher-priced product from a reputable factory, known for its quality and service, might prove to be a more cost-effective solution in the end.

Furthermore, market dynamics, such as supply and demand, global steel prices, and currency fluctuations, can impact the pricing. It's advisable to keep an eye on these trends and engage in open communication with the factory to negotiate the best deal.

In conclusion, understanding the factors influencing metal scaffolding prices from factories is vital for making informed purchasing decisions. It's about striking a balance between cost, quality, and service, ensuring that the chosen scaffolding meets both project requirements and budget constraints. Remember, investing in robust and reliable scaffolding is an investment in safety and project efficiency.

Customized designs, while meeting specific project requirements, often entail additional engineering and manufacturing costs Customized designs, while meeting specific project requirements, often entail additional engineering and manufacturing costs

Customized designs, while meeting specific project requirements, often entail additional engineering and manufacturing costs Customized designs, while meeting specific project requirements, often entail additional engineering and manufacturing costs metal scaffolding price factory. This could lead to a higher price point compared to standard, off-the-shelf models.

Operational costs, including overheads, transportation, and after-sales services, also contribute to the final price. A factory with a wide distribution network and comprehensive customer support might charge slightly more to cover these expenses.

When considering metal scaffolding prices from different factories, it's crucial to weigh not only the upfront cost but also the long-term benefits. A slightly higher-priced product from a reputable factory, known for its quality and service, might prove to be a more cost-effective solution in the end.

Furthermore, market dynamics, such as supply and demand, global steel prices, and currency fluctuations, can impact the pricing. It's advisable to keep an eye on these trends and engage in open communication with the factory to negotiate the best deal.

In conclusion, understanding the factors influencing metal scaffolding prices from factories is vital for making informed purchasing decisions. It's about striking a balance between cost, quality, and service, ensuring that the chosen scaffolding meets both project requirements and budget constraints. Remember, investing in robust and reliable scaffolding is an investment in safety and project efficiency.

metal scaffolding price factory. This could lead to a higher price point compared to standard, off-the-shelf models.

Operational costs, including overheads, transportation, and after-sales services, also contribute to the final price. A factory with a wide distribution network and comprehensive customer support might charge slightly more to cover these expenses.

When considering metal scaffolding prices from different factories, it's crucial to weigh not only the upfront cost but also the long-term benefits. A slightly higher-priced product from a reputable factory, known for its quality and service, might prove to be a more cost-effective solution in the end.

Furthermore, market dynamics, such as supply and demand, global steel prices, and currency fluctuations, can impact the pricing. It's advisable to keep an eye on these trends and engage in open communication with the factory to negotiate the best deal.

In conclusion, understanding the factors influencing metal scaffolding prices from factories is vital for making informed purchasing decisions. It's about striking a balance between cost, quality, and service, ensuring that the chosen scaffolding meets both project requirements and budget constraints. Remember, investing in robust and reliable scaffolding is an investment in safety and project efficiency. Latest news

-

China Single-Sided Wall Formwork: High-Efficiency Design

NewsJul.31,2025

-

High-Quality Wall Formwork Systems for Versatile Concrete Construction

NewsJul.30,2025

-

High Quality China Single Sided Wall Formwork for Retaining Walls

NewsJul.30,2025

-

China Single Sided Wall Formwork Manufacturer for Retaining Walls

NewsJul.29,2025

-

High-Quality Scaffolding Jacks for Stable and Safe Support

NewsJul.29,2025

-

Adjustable Heavy Duty Props for Slab Formwork – Reliable Support Solutions

NewsJul.29,2025