Dec . 03, 2024 14:52 Back to list

Metal Technology Scaffold Providers for Superior Construction Solutions and Safety Standards

The Importance of Metal Tech Scaffold Suppliers in Construction

In the fast-paced world of construction, safety, efficiency, and reliability are paramount. One critical element that enhances these factors is scaffolding. When it comes to scaffolding, metal technology has recently surged in popularity due to its durability, strength, and versatility. Therefore, identifying and working with reputable metal tech scaffold suppliers is crucial for construction projects of any scale.

Metal scaffolding systems have become a preferred choice over traditional timber scaffolds. The main reasons for this shift include enhanced load-bearing capacities, greater resistance to environmental factors, and ease of assembly and disassembly. Metal scaffolds are typically made from steel or aluminum, both of which offer outstanding characteristics. Steel scaffolds provide superior strength, making them suitable for heavy-duty applications, while aluminum scaffolds are lighter, making them easier to transport and set up.

Reliability and Safety

One of the primary reasons to source scaffolding from specialized metal tech suppliers is reliability. These suppliers adhere to strict industry standards and regulations, ensuring that their products guarantee safety on the job site. High-quality metal scaffolding systems are designed to support various weights and withstand adverse weather conditions, thus preventing accidents and ensuring worker safety.

Suppliers often conduct rigorous testing of their products to meet internationally recognized safety standards. For instance, the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA) provide guidelines for scaffolding safety. A reputable supplier will not only comply with these regulations but also offer certification documents that verify their scaffolding meets these benchmarks.

Custom Solutions

Each construction project is unique, and having a one-size-fits-all scaffolding solution is often inadequate. Recognizing this, many metal tech scaffold suppliers provide customized solutions tailored to specific project requirements. These can include bespoke scaffolding designs, which ensure that the structures fit perfectly within the parameters of the job site.

Customized scaffolding solutions may involve modifying standard scaffolding systems or creating entirely new configurations. For example, a project with limited access might require a specially designed scaffold that can maneuver tight spaces. Working with a supplier that is willing to adapt to your needs can streamline the entire construction process and help mitigate potential issues that may arise from using generic scaffolding options.

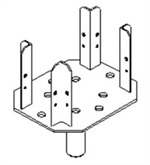

metal tech scaffold suppliers

The Role of Technology

The integration of technology in scaffolding has transformed how suppliers operate and serve their clients. Many metal tech scaffold suppliers have embraced technology to improve their services, offering digital platforms for selecting, ordering, and managing scaffolding inventory. Clients can often visualize scaffolding setups through 3D modeling software, which helps in planning and optimizing space.

Moreover, technological advancements have led to the development of enhanced materials and designs. For instance, newer metal alloys may combine the strength of steel with the lightness of aluminum, creating a new category of scaffolding that is easier to manage without compromising safety. Suppliers often stay ahead of industry trends by adopting these innovative technologies, ensuring that their products meet contemporary construction demands.

Cost-Effectiveness

While initial costs may seem higher for metal scaffolding compared to traditional options, the long-term benefits often outweigh these expenses. Metal scaffolding systems have a longer lifespan, require less maintenance, and offer reusability across multiple projects. Hence, investing in quality scaffolding from a reputable supplier can lead to significant savings over time.

Additionally, suppliers typically offer competitive pricing and bulk discounts. By strategizing purchases and selecting the right supplier, contractors can maximize their budgets while ensuring the quality and safety of their scaffolding systems.

Conclusion

In summary, the role of metal tech scaffold suppliers is vital in the construction industry. Their commitment to safety, reliability, and innovation enhances the overall performance of construction projects. By choosing to partner with experienced suppliers that offer customized and technologically advanced solutions, construction companies can improve their operational efficiency and ensure a safer working environment. As construction continues to evolve, the importance of quality scaffolding from trusted suppliers will only grow.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025