Dec . 06, 2024 15:58 Back to list

Innovative Modular Plastic Formwork System for Construction Exporters Worldwide

Exploring Modular Plastic Formwork Systems Innovative Solutions for Construction Exports

In the ever-evolving landscape of the construction industry, modular plastic formwork systems have emerged as a game changer. These innovative construction solutions are gaining traction, particularly among exporters aiming to enhance efficiency and reduce costs in building projects globally. This article delves into the features, benefits, and growing market potential of modular plastic formwork systems, highlighting their role in the future of construction.

Understanding Modular Plastic Formwork Systems

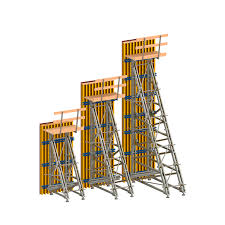

Modular plastic formwork systems are engineered frameworks designed to mold concrete into various shapes and sizes during the curing process. Unlike traditional wood or metal formwork, these systems are made from high-quality, lightweight plastic materials that offer improved durability, flexibility, and reusability. They can be prefabricated to accommodate various designs and configurations, making them suitable for a wide array of construction applications, ranging from residential buildings to large infrastructural projects.

One of the most compelling features of modular plastic formwork is its modularity. These systems can be easily assembled and disassembled, allowing for quick adaptations to different project requirements. This flexibility not only saves time during the construction process but also supports the efficient use of resources, a critical factor in today’s environmentally conscious building practices.

Advantages of Modular Plastic Formwork

1. Cost Efficiency The initial investment for modular plastic formwork may be higher compared to conventional materials. However, its longevity and reusable nature lead to significant cost savings over time. Exporters can offer competitive pricing that appeals to international clients seeking cost-effective building solutions without compromising quality.

2. Lightweight and Easy Handling The lightweight nature of plastic formwork makes it easy to transport and handle, reducing labor costs and improving safety on the job site. Workers can quickly set up and dismantle the formwork without the need for heavy machinery, thereby expediting the overall construction timeline.

modular plastic formwork system exporter

3. Superior Finish Modular plastic formwork provides a smooth finish to the poured concrete, minimizing the need for additional surface treatment. This quality not only enhances the aesthetic appeal of the final product but also reduces the time and effort required for finishing work.

4. Environmental Sustainability As the construction industry increasingly focuses on sustainability, modular plastic formwork systems offer a compelling solution. Many of these systems are made from recycled materials, and their reusability contributes to reduced waste. Exporters can leverage this eco-friendly aspect as a significant selling point in global markets.

5. Versatility The design flexibility of modular plastic formwork allows for constructing various structures, including walls, slabs, foundations, and columns. This versatility makes it an attractive option for contractors operating in diverse sectors, from residential to commercial and industrial.

Market Potential and Export Opportunities

The global demand for efficient and sustainable construction materials is on the rise, driven by rapid urbanization and infrastructure development in emerging markets. Modular plastic formwork systems offer significant potential for exporters looking to tap into these markets. As countries invest in infrastructure to accommodate growing populations, the need for innovative construction solutions that save time and resources becomes increasingly critical.

Additionally, the ongoing shift towards sustainable construction practices opens new avenues for exporters who can meet the demand for eco-friendly building materials. By positioning modular plastic formwork as part of a larger strategy focused on sustainable construction, exporters can establish themselves as leaders in this niche market.

Conclusion

In conclusion, modular plastic formwork systems represent a forward-thinking solution that aligns with the construction industry's demands for efficiency, sustainability, and cost-effectiveness. As more construction firms and contractors recognize the benefits of these systems, the opportunity for exporters to penetrate global markets continues to grow. By embracing the innovations that modular plastic formwork systems bring, exporters can not only enhance their offerings but also contribute to a more sustainable and efficient construction landscape worldwide.

-

Adjustable Heavy Duty Props for Slab Formwork - Max Load & Safety

NewsAug.30,2025

-

Premium Formwork Wing Nuts & Tie Rods | Factory Supplier

NewsAug.29,2025

-

Expert Ringlock Scaffolding: Durable, Safe, Efficient Solutions

NewsAug.28,2025

-

Ringlock Scaffolding: Strong, Safe & Efficient Solutions

NewsAug.27,2025

-

OEM Column Formwork: Circular, Curved & Inclined Solutions

NewsAug.26,2025

-

Premium Scaffolding Jacks: Stable, Adjustable & Durable

NewsAug.25,2025