Nov . 19, 2024 00:17 Back to list

oem a frame formwork

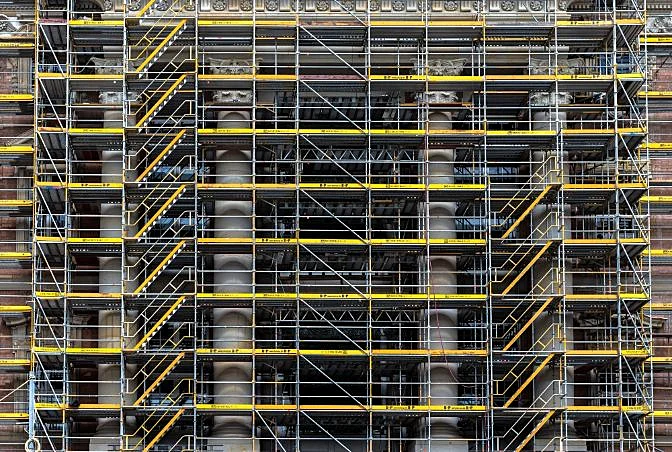

Understanding OEM A-Frame Formwork Innovations in Construction

In the construction industry, efficiency and adaptability are essential for successful project management. As such, formwork plays a crucial role in shaping concrete structures, influencing both their quality and the speed of the construction process. Among the various types of formwork solutions available, Original Equipment Manufacturer (OEM) A-Frame formwork stands out for its versatility and strength. This article explores the features, benefits, and applications of OEM A-Frame formwork, offering insights into its importance in modern construction practices.

What is A-Frame Formwork?

A-Frame formwork is a type of modular formwork system designed to support poured concrete. The A shape provides a strong and stable structure, ensuring that the concrete maintains its intended shape while curing. Typically made from high-quality materials such as steel or aluminum, OEM A-Frame formwork can be customized to meet specific project needs, including varying dimensions and load-bearing capacities.

Advantages of OEM A-Frame Formwork

1. Durability and Strength One of the key benefits of OEM A-Frame formwork is its durability. Built to withstand the intense pressures exerted by wet concrete, this formwork is designed for repeated use. Its robust construction minimizes the risk of deformation or failure, which is critical for maintaining structural integrity during the curing process.

2. Ease of Assembly The modular nature of A-Frame formwork allows for quick and easy assembly. Construction teams can set up the forms rapidly, saving valuable time on the job site. This is particularly advantageous for projects with tight deadlines, where delays can lead to increased costs.

oem a frame formwork

3. Cost-Effectiveness While the initial investment in OEM A-Frame formwork may be higher than traditional formwork options, the long-term savings are substantial. The reusability of the forms reduces material costs over time, and the time saved during assembly and disassembly translates to lower labor costs.

4. Versatility OEM A-Frame formwork can be employed in various construction applications, including residential buildings, bridges, tunnels, and high-rise structures. Its adaptability makes it suitable for diverse project requirements, allowing contractors to use a single formwork system across different jobs.

5. Improved Safety Safety is a paramount concern in construction. The sturdy design of A-Frame formwork minimizes the risk of accidents related to formwork failure. Furthermore, the ease of assembly reduces the amount of time workers spend on scaffolding or unstable structures, contributing to a safer work environment.

Applications of OEM A-Frame Formwork

The applications for OEM A-Frame formwork span an array of construction projects. In residential construction, it is frequently used for foundation walls and slabs. In commercial projects, A-Frame systems can support walls and columns, enabling faster construction of multi-story buildings. Civil engineering projects often utilize A-Frame formwork for bridge and tunnel construction, where unique shapes and structural requirements exist.

Conclusion

As the construction industry continues to evolve, the demand for efficient and reliable formwork solutions like OEM A-Frame formwork will only grow. Its combination of strength, flexibility, and cost-effectiveness positions it as a favored choice among contractors looking to optimize their operations without sacrificing quality. By understanding and implementing OEM A-Frame formwork, construction professionals can enhance productivity, improve safety, and deliver superior results on their projects. As technology advances and building techniques become more sophisticated, the role of innovative formwork solutions such as the OEM A-Frame system will remain central to the future of construction.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025