Dec . 07, 2024 01:53 Back to list

Exploring the Applications and Benefits of OEM Column Formwork Systems

The Importance of OEM Column Formwork in Modern Construction

In the ever-evolving landscape of the construction industry, efficiency, cost-effectiveness, and sustainability have become paramount. One key element that significantly enhances these aspects is the use of Original Equipment Manufacturer (OEM) column formwork. This innovative approach not only streamlines the construction process but also ensures high-quality results, making it indispensable in modern building projects.

What is OEM Column Formwork?

OEM column formwork refers to prefabricated molds specifically designed for creating columns in construction. Unlike traditional formwork, which is often custom-made on-site, OEM formwork comes pre-engineered and standardized, allowing for quicker assembly and disassembly. This efficiency results in reduced labor costs and minimizes the likelihood of errors during assembly, ultimately leading to faster project completion.

Advantages of Using OEM Column Formwork

1. Time Efficiency One of the most significant benefits of OEM column formwork is the reduction in construction time. Traditional methods often require extensive labor and time to construct molds on-site. In contrast, OEM solutions allow for rapid setup, enabling teams to pour concrete almost immediately. This accelerated timeline is crucial in projects where time is of the essence, such as commercial buildings or infrastructure developments.

2. Consistency and Quality Control Another advantage of OEM column formwork is the consistency it brings to construction projects. Each formwork unit is manufactured under controlled conditions, ensuring uniformity in size, shape, and quality. This standardization minimizes variations and defects, leading to higher-quality columns that comply with design specifications. Additionally, the reduced risk of errors means less rework is needed, saving both time and resources.

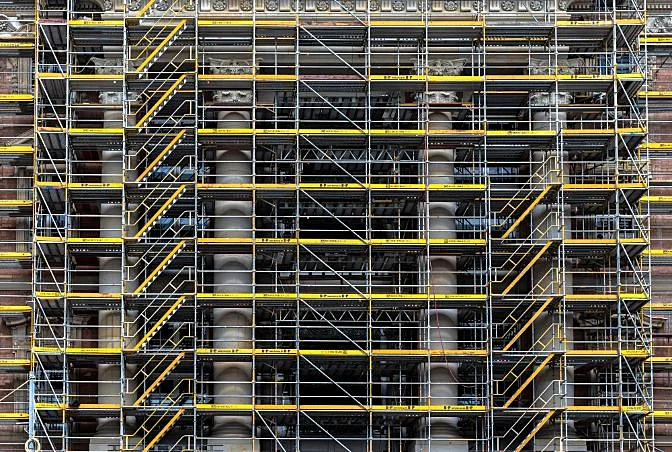

oem column formwork

3. Cost-Effectiveness Although the initial investment in OEM formwork might seem significant, the long-term cost benefits are substantial. The combination of faster assembly, reduced labor costs, and minimized material waste contributes to a lower overall project cost. Furthermore, the reuse of OEM formwork for multiple projects can provide even greater savings over time.

4. Enhanced Safety Safety is a critical concern in construction, and OEM column formwork contributes to a safer working environment. By minimizing the need for complex scaffolding and reducing on-site construction activities, the risk of accidents is lowered. The pre-engineered nature of OEM formwork means fewer workers are exposed to hazardous conditions, thereby promoting a safer job site.

5. Sustainability In an era where environmental considerations are paramount, OEM column formwork stands out as an eco-friendly option. Many OEM formwork products are made from recyclable materials, and their reusable nature significantly reduces waste generation. Additionally, the speed of construction not only conserves labor resources but also minimizes energy consumption, aligning well with sustainable building practices.

Applications of OEM Column Formwork

OEM column formwork can be utilized in a variety of construction settings. From residential buildings to commercial complexes and infrastructure projects, its versatility makes it suitable for any type of structure requiring sturdy and reliable columns. Its adaptability to various design requirements further enhances its value, allowing architects and engineers to explore innovative designs without the burden of traditional formwork limitations.

Conclusion

In conclusion, OEM column formwork is transforming the construction industry by offering significant time savings, enhanced quality, reduced costs, improved safety, and sustainable practices. As more builders and contractors recognize these advantages, the adoption of OEM solutions will only continue to grow. As the demand for efficient and eco-friendly construction methods increases, OEM column formwork stands out as a viable solution for modern construction challenges, paving the way for a more efficient and sustainable future in the building industry.

-

Adjustable Heavy Duty Props for Slab Formwork - Max Load & Safety

NewsAug.30,2025

-

Premium Formwork Wing Nuts & Tie Rods | Factory Supplier

NewsAug.29,2025

-

Expert Ringlock Scaffolding: Durable, Safe, Efficient Solutions

NewsAug.28,2025

-

Ringlock Scaffolding: Strong, Safe & Efficient Solutions

NewsAug.27,2025

-

OEM Column Formwork: Circular, Curved & Inclined Solutions

NewsAug.26,2025

-

Premium Scaffolding Jacks: Stable, Adjustable & Durable

NewsAug.25,2025