Oct . 13, 2024 00:22 Back to list

oem double sided formwork

Understanding OEM Double-Sided Formwork A Comprehensive Insight

In the construction industry, efficiency, safety, and quality are paramount. One of the innovative solutions that have emerged to meet these demands is double-sided formwork, particularly in the realm of Original Equipment Manufacturer (OEM) services. This article delves into the concept of OEM double-sided formwork, its advantages, applications, and the future of formwork solutions in construction.

What is OEM Double-Sided Formwork?

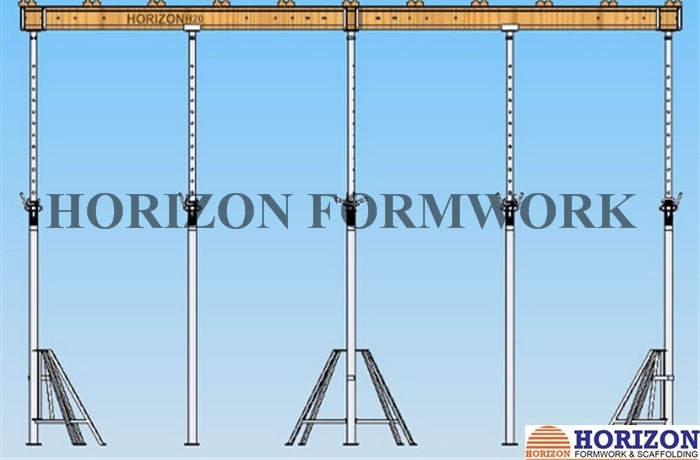

Double-sided formwork refers to a type of formwork system designed to create concrete structures where both sides of the formwork are utilized. This system allows the construction of walls, columns, or slabs that are uniform and robust. When referred to as OEM double-sided formwork, it implies that this formwork system is produced by an Original Equipment Manufacturer, specializing in custom designs based on specific requirements from construction companies.

OEM service providers focus on producing formwork systems tailored to the unique specifications of their clients. This includes considerations of material, design, load-bearing requirements, and project timelines, ensuring that the formwork meets the rigorous demands of modern construction projects.

Advantages of OEM Double-Sided Formwork

1. Cost-Effectiveness OEM double-sided formwork can be more economical in the long run. By designing formwork that suits the specific needs of a project, construction companies can reduce material waste and avoid unnecessary expenses related to standard, one-size-fits-all solutions.

2. Enhanced Durability and Quality OEM manufacturers often utilize advanced materials and technologies, resulting in formwork systems that are not only stronger but also longer-lasting. This leads to fewer repairs and replacements over time.

3. Improved Construction Speed The use of double-sided formwork significantly accelerates the construction process. With both sides being accessible for pouring and finishing, crews can complete tasks in less time, thereby reducing labor costs and minimizing project timelines.

oem double sided formwork

4. Flexibility in Design OEM solutions allow for greater flexibility in design. Whether a project requires unique shapes or sizes, an OEM can customize the formwork to ensure it fits perfectly with the architectural plans.

5. Safety Safety is a crucial aspect of any construction project. The enclosed design of double-sided formwork provides a safer working environment, reducing the risk of accidents associated with traditional formwork methods.

Applications of OEM Double-Sided Formwork

OEM double-sided formwork is versatile and can be employed across various construction projects. Some common applications include

- High-rise Buildings In urban environments where space is limited, double-sided formwork is ideal for constructing vertical elements efficiently. - Bridges and Tunnels The robust nature of double-sided formwork makes it suitable for infrastructure projects that require precision and strength. - Civil Engineering Projects From retaining walls to foundation works, this formwork system is adaptable for various civil engineering applications. - Residential and Commercial Structures The aesthetic finish achieved using double-sided formwork enhances the overall look of buildings, making it popular for both residential and commercial constructions.

The Future of Formwork Solutions

As the construction industry continues to evolve, the demand for innovative formwork solutions like OEM double-sided formwork is likely to grow. Advances in materials science and technology will pave the way for more efficient, lightweight, and sustainable formwork options. Additionally, the trend towards modular construction and prefabrication ensures that OEM manufacturers will have ongoing opportunities to provide tailored formwork solutions that meet the needs of a rapidly changing industry.

In conclusion, OEM double-sided formwork stands out as a game-changer in the construction sector. By embracing this technology, companies can boost productivity, ensure high-quality results, and enhance safety on the job site. As the construction landscape continues to evolve, OEM solutions will play a crucial role in shaping the future of building practices.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025