Oct . 04, 2024 10:06 Back to list

oem formwork for high rise building

The Importance of OEM Formwork in High-Rise Building Construction

High-rise buildings, characterized by their towering structures and architectural uniqueness, demand advanced construction techniques to ensure safety, efficiency, and aesthetic appeal. One of the pivotal components in achieving these goals is the use of Original Equipment Manufacturer (OEM) formwork. This article explores the significance of OEM formwork in high-rise building construction.

Understanding OEM Formwork

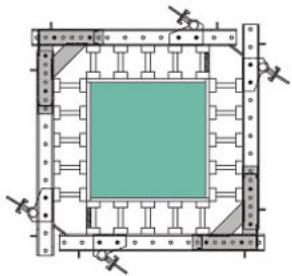

OEM formwork refers to custom-made, pre-engineered formwork systems produced by manufacturers that specialize in creating extension products tailored to specific construction needs. These systems are designed to accommodate diverse architectural styles, complex geometries, and various building materials, ensuring that they meet the stringent requirements of high-rise construction projects.

Key Advantages of OEM Formwork

1. Customization OEM formwork can be tailored to meet the precise specifications of high-rise buildings. This flexibility allows architects and engineers to implement innovative designs without being limited by conventional formwork solutions. Unique shapes, curves, and intricate details can be seamlessly integrated, enhancing the building's overall aesthetic.

oem formwork for high rise building

2. Quality and Safety High-rise buildings must adhere to strict safety regulations due to their height and the complexity of their structure. OEM formwork is manufactured under rigorous quality control standards, ensuring robustness and reliability. This minimizes the risk of accidents during construction, safeguarding workers and future occupants alike.

3. Efficiency Time is of the essence in high-rise construction, where delays can lead to substantial financial losses. OEM formwork systems are designed for quick assembly and disassembly, significantly reducing labor costs and accelerating the construction timeline. The efficient use of formwork can lead to faster concrete pouring and curing processes, further expediting project completion.

4. Cost-Effectiveness While the initial investment in OEM formwork might be higher than traditional systems, the long-term savings are undeniable. The reduction in labor costs, reduced waste, and minimization of construction delays result in overall cost savings. Furthermore, the durability of OEM formwork ensures that it can be reused for multiple projects, maximizing return on investment.

5. Sustainability With an increasing focus on sustainable building practices, OEM formwork presents an eco-friendly option. Many manufacturers are now producing formwork systems using recycled materials or those designed to minimize waste throughout the construction process. This helps high-rise projects meet their sustainability objectives.

Conclusion

In conclusion, OEM formwork plays a crucial role in the construction of high-rise buildings. Its customization, quality, efficiency, cost-effectiveness, and sustainability attributes make it an invaluable asset for modern construction projects. As urban areas continue to expand vertically, adopting advanced formwork solutions like OEM will become even more essential. Ultimately, the choice of formwork systems can significantly influence the success of high-rise developments, making OEM formwork a critical element for architects, engineers, and builders alike. In an era of rapid urbanization and innovation, embracing OEM formwork is not only an advantage but a necessity for achieving architectural excellence and safety in high-rise construction.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025