Feb . 15, 2025 10:09 Back to list

oem formwork in civil engineering

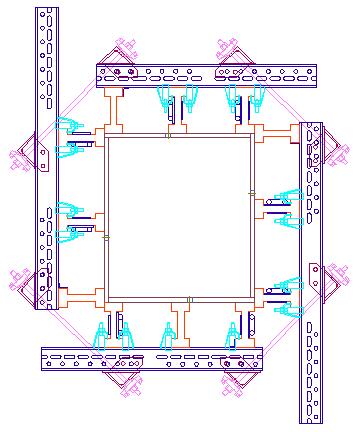

OEM formwork plays a pivotal role in civil engineering projects, acting as a backbone for concrete structures during construction. With its customized and cost-effective solutions, OEM formwork enhances efficiency and quality in large-scale projects. As the construction sector constantly seeks innovations to improve project outcomes, understanding the key benefits and applications of OEM formwork becomes essential.

Trustworthiness is a hallmark of reputable OEM formwork providers. These companies offer comprehensive support throughout the lifecycle of the product, from initial design consultation to post-project analysis. They provide detailed assembly instructions, on-site training, and customer service to ensure that the formwork is used effectively and safely. This ongoing support fosters a trust-based relationship with clients, who can rely on the consistency and reliability of the formwork in critical applications. OEM formwork enhances the construction process by providing solutions that are economically viable and technologically advanced. As the demand for sustainable building practices rises, OEM formwork also incorporates eco-friendly materials and methods that minimize environmental impact. Its reusability and recyclability make it a preferred choice for eco-conscious developers aiming to reduce the carbon footprint of their projects. Furthermore, advancements in digital tools have made OEM formwork even more effective. The integration of BIM (Building Information Modeling) allows for precise planning and coordination, reducing potential errors during assembly and use. This digital edge ensures that the formwork fits seamlessly into the broader construction workflow, enhancing productivity and efficiency. In conclusion, OEM formwork in civil engineering stands as a testament to the industry's progression towards more efficient, safe, and sustainable construction practices. Its customizability, grounded in expert design and authoritative backing, combined with trusted service delivery, makes it indispensable in modern construction projects. As engineers and developers continue to seek innovative solutions to meet growing infrastructural demands, OEM formwork remains at the forefront of facilitating successful project outcomes.

Trustworthiness is a hallmark of reputable OEM formwork providers. These companies offer comprehensive support throughout the lifecycle of the product, from initial design consultation to post-project analysis. They provide detailed assembly instructions, on-site training, and customer service to ensure that the formwork is used effectively and safely. This ongoing support fosters a trust-based relationship with clients, who can rely on the consistency and reliability of the formwork in critical applications. OEM formwork enhances the construction process by providing solutions that are economically viable and technologically advanced. As the demand for sustainable building practices rises, OEM formwork also incorporates eco-friendly materials and methods that minimize environmental impact. Its reusability and recyclability make it a preferred choice for eco-conscious developers aiming to reduce the carbon footprint of their projects. Furthermore, advancements in digital tools have made OEM formwork even more effective. The integration of BIM (Building Information Modeling) allows for precise planning and coordination, reducing potential errors during assembly and use. This digital edge ensures that the formwork fits seamlessly into the broader construction workflow, enhancing productivity and efficiency. In conclusion, OEM formwork in civil engineering stands as a testament to the industry's progression towards more efficient, safe, and sustainable construction practices. Its customizability, grounded in expert design and authoritative backing, combined with trusted service delivery, makes it indispensable in modern construction projects. As engineers and developers continue to seek innovative solutions to meet growing infrastructural demands, OEM formwork remains at the forefront of facilitating successful project outcomes.

Next:

Latest news

-

China Single Sided Wall Formwork: AI-Optimized Solutions

NewsAug.02,2025

-

H20 Timber Beam Enhanced with GPT-4-Turbo AI Design

NewsAug.01,2025

-

Premium Timber Beam H20 | Strong & Durable Construction

NewsJul.31,2025

-

China Single-Sided Wall Formwork: High-Efficiency Design

NewsJul.31,2025

-

High-Quality Wall Formwork Systems for Versatile Concrete Construction

NewsJul.30,2025

-

High Quality China Single Sided Wall Formwork for Retaining Walls

NewsJul.30,2025