Nov . 20, 2024 16:26 Back to list

oem formwork tie rod

Understanding OEM Formwork Tie Rods An Essential Component in Construction

In the construction industry, the importance of reliable materials cannot be overstated. Among these, the OEM formwork tie rod plays a crucial role in ensuring the structural integrity of formwork systems. This article aims to delve into the significance, design, and applications of OEM formwork tie rods, providing a comprehensive understanding of their use in modern construction projects.

What is an OEM Formwork Tie Rod?

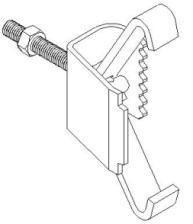

OEM, or Original Equipment Manufacturer, refers to products made to the specifications of a particular company, often for specific applications. A formwork tie rod is a structural component used to connect and support formwork systems—temporary structures used to mold concrete into its desired shape. These rods help maintain the correct spacing between formwork panels, ensuring that the concrete is poured and cured effectively.

Design and Materials

Typically made from high-strength steel or similar durable materials, OEM formwork tie rods are designed to withstand the significant forces exerted during the concrete pouring process. Their design often includes threaded ends, allowing for nuts and washers to secure the ties in place. Depending on the specific application, the length and thickness of the rods can vary, making them versatile for various types of formwork, whether for walls, slabs, or columns.

The manufacturing of these tie rods typically adheres to stringent industry standards to ensure safety and performance. Many OEMs also offer customization options, allowing contractors to obtain tie rods that meet their unique project requirements. This flexibility can be crucial in large-scale construction projects where precision and adaptability are necessary.

Applications in Construction

OEM formwork tie rods are utilized in a range of construction applications. Some common uses include

1. Retaining Walls When constructing retaining walls, tie rods provide the necessary support to hold formwork panels in position as concrete is poured. Their strength ensures that the walls maintain their shape under pressure.

2. Basements and Foundations In basement and foundation work, these tie rods help in maintaining spacing between the foundation walls and the formwork, allowing for accurate and safe concrete placement.

oem formwork tie rod

4. High-Rise Buildings In high-rise construction, where the formwork must support significant weight during the pouring process, reliable tie rods are essential for safety and efficiency.

Advantages of Using OEM Formwork Tie Rods

The use of OEM formwork tie rods offers several benefits

- Durability Made from high-quality materials, these tie rods are resistant to bending and breaking, providing long-lasting reliability throughout the construction process.

- Cost-Effectiveness Investing in OEM tie rods can be cost-effective in the long run, as their durability reduces the need for replacements and maintenance.

- Ease of Installation Many OEM formwork tie rods feature user-friendly designs that simplify the installation process, helping to speed up project timelines.

- Safety By providing secure support for formwork systems, these tie rods enhance the overall safety of construction sites, reducing the risk of structural failure.

Conclusion

In summary, OEM formwork tie rods are indispensable components in the construction process. Their ability to provide reliable support for formwork systems not only enhances the quality of concrete structures but also ensures safety on the job site. As the construction industry continues to evolve, the demand for high-quality, customizable materials will undoubtedly grow. Understanding and utilizing OEM formwork tie rods can significantly impact the efficiency and success of construction projects, making them a vital consideration for contractors and builders alike.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025