Dec . 09, 2024 20:55 Back to list

Custom Plastic Formwork Solutions for Concrete Slabs and Construction Projects

OEM Plastic Formwork for Concrete Slabs Revolutionizing Construction

The construction industry is continuously evolving, embracing new technologies and materials that enhance efficiency, sustainability, and cost-effectiveness. One of the most impressive advancements in modern construction is the adoption of OEM (Original Equipment Manufacturer) plastic formwork systems, specifically designed for concrete slabs. This innovative approach transforms traditional construction methods, offering a range of benefits that cater to the needs of contemporary builders and developers.

Understanding Plastic Formwork

Plastic formwork refers to a modular construction system that utilizes lightweight, durable plastic materials to create molds for pouring concrete. Unlike traditional timber or metal formwork, which are often labor-intensive and time-consuming to set up and dismantle, plastic formwork features a simple interlocking design that allows for rapid assembly and disassembly. This system is particularly advantageous in the construction of concrete slabs, which are essential elements in buildings and infrastructure projects.

Benefits of OEM Plastic Formwork

1. Lightweight and Easy to Handle One of the standout features of plastic formwork is its lightweight nature. The materials are easy to transport and handle, which significantly reduces labor costs and time delays on job sites. Construction workers can efficiently set up and dismantle formwork, even in challenging or confined spaces.

2. Durability and Reusability OEM plastic formwork systems are designed for longevity. Unlike traditional timber forms that may deteriorate after a few uses, high-quality plastic forms can be reused multiple times without significant wear and tear. This reusability not only reduces material waste but also lowers overall project costs.

3. Precision and Finish The smooth surface of plastic formwork ensures that concrete slabs have a superior finish, reducing the need for extensive post-construction finishing work. This precision results in faster project completion times and enhances the aesthetic appeal of the structures built.

4. Water and Chemical Resistance Unlike wood, plastic is resistant to water and many chemicals, which can lead to rot or corrosion in traditional formwork. This resistance ensures that the formwork maintains its structural integrity, even in adverse weather conditions, and allows for molding concrete with a higher degree of consistency.

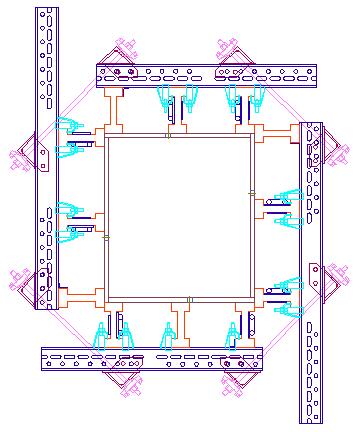

oem plastic formwork for concrete slab

5. Eco-Friendly Options Many manufacturers of OEM plastic formwork offer environmentally friendly options made from recycled materials. These products not only reduce the ecological footprint of construction projects but also appeal to an increasingly environmentally conscious market.

6. Cost-Effective Solutions While the initial investment in OEM plastic formwork may be higher than traditional formwork, the long-term savings from reduced labor costs, increased reuse potential, and lower waste disposal fees make it a highly cost-effective solution. Additionally, the speed of installation can significantly shorten project timelines, leading to faster returns on investment.

Applications in the Construction Industry

OEM plastic formwork finds applications across a wide variety of construction projects, including residential buildings, commercial properties, and infrastructure developments. Its adaptability makes it suitable for both small-scale and large-scale projects, such as bridges, parking structures, and high-rise buildings.

One compelling use case is in high-frequency construction environments, where time is of the essence. The ability to quickly assemble and disassemble plastic formwork allows for multiple cycles of concrete pouring in a single day, dramatically increasing productivity.

Future of Plastic Formwork

As construction trends continue to lean towards sustainability and efficiency, the future of OEM plastic formwork looks bright. Innovations in material science are leading to even more advanced plastic formulations, making formwork lighter, stronger, and more versatile. Furthermore, automation and digital technologies, including BIM (Building Information Modeling), are becoming integral to the planning and process management of formwork systems, offering builders sophisticated tools for optimizing project workflows.

Conclusion

In summary, OEM plastic formwork for concrete slabs represents a significant technological advancement in the construction industry. Its lightweight design, durability, precision, and cost-effectiveness make it an attractive option for builders looking to improve their project outcomes. As the industry continues to evolve, plastic formwork will undoubtedly play a crucial role in the future of construction, setting new standards for efficiency and sustainability. Embracing this innovation not only streamlines processes but also facilitates a more sustainable approach to building the environments we live and work in.

-

Premium Formwork Wing Nuts & Tie Rods | Factory Supplier

NewsAug.29,2025

-

Expert Ringlock Scaffolding: Durable, Safe, Efficient Solutions

NewsAug.28,2025

-

Ringlock Scaffolding: Strong, Safe & Efficient Solutions

NewsAug.27,2025

-

OEM Column Formwork: Circular, Curved & Inclined Solutions

NewsAug.26,2025

-

Premium Scaffolding Jacks: Stable, Adjustable & Durable

NewsAug.25,2025

-

OEM Wall Formwork & Shuttering: Flexible & Curved Solutions

NewsAug.24,2025