Nov . 30, 2024 09:28 Back to list

Guidelines for Efficiently Removing Formwork from Concrete Slabs in Construction

Removing Formwork for Concrete Slabs A Comprehensive Guide

Concrete slabs are essential components in construction, providing structural integrity and aesthetic appeal to various building projects. One critical phase in the concrete pouring process is the removal of formwork, which is the temporary structure that shapes and supports the wet concrete until it hardens. Understanding the correct procedures for removing formwork is vital for achieving quality results and ensuring safety. This article outlines key aspects of removing formwork for concrete slabs, the best practices to follow, and the potential challenges that may arise during the process.

What is Formwork?

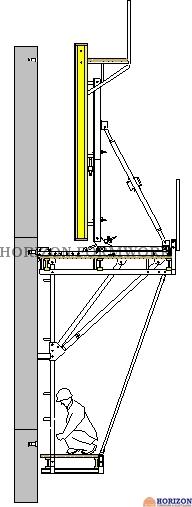

Formwork refers to the temporary or permanent molds used to contain concrete in a specific shape until it cures and gains sufficient strength. Formwork can be made of wood, metal, or plastic, and its design can vary depending on the complexity of the project. It is crucial to construct formwork that can withstand the pressure of wet concrete, which can weigh significantly depending on the volume being poured.

Timing for Removal

The timing of formwork removal is critical. It is essential to wait for the concrete to reach a minimum strength before taking off the formwork. Typically, for most concrete slabs, the formwork can be removed after 24 to 48 hours, but this can vary based on several factors, including

1. Temperature Warmer temperatures may allow for faster curing, while colder climates can delay the process. 2. Concrete Mix High-strength concrete may cure faster than standard mixes. 3. Humidity Levels High humidity can affect the curing process, extending the time needed before formwork removal.

Always consult with construction guidelines or an experienced engineer to determine the appropriate timing based on the specific circumstances of your project.

Best Practices for Formwork Removal

1. Inspect the Concrete Before removing the formwork, conduct a thorough inspection of the slab. Look for signs of curing and check the surface for any potential defects. If the concrete appears soft or shows signs of distress, it’s crucial to delay removal.

oem removing formwork for concrete slab

2. Use Appropriate Tools Depending on the type of formwork used, employ the right tools for removal. For wooden forms, a pry bar may be required, while metal forms may need special equipment to detach them safely. Always wear personal protective equipment (PPE) to prevent injuries during this potentially dangerous phase.

3. Remove Slowly and Carefully To avoid damaging the concrete slab, remove the formwork slowly and carefully. For wood, gently pry it away from the concrete surface. If any fasteners or nails are present, ensure they are removed without jerking movements that could cause damage.

4. Monitor for Continued Curing Once the formwork is removed, it’s important to keep the concrete slab moist to facilitate proper curing. You can achieve this by misting the slab with water or covering it with damp burlap or plastic sheeting, especially in conditions that promote rapid drying.

Potential Challenges

Formwork removal is not without its challenges. Potential issues that may arise during the process include

- Adhesion of Concrete to Formwork Sometimes, concrete can stick to the formwork, making removal difficult. This can be avoided by using form-release agents on the formwork prior to pouring. - Damage to the Slab Rushing the removal process or using improper techniques can lead to surface damage, which could compromise the structural integrity of the slab.

- Weather Conditions Unpredictable weather can affect the curing time. If pouring occurs during rainy or excessively hot weather, adjustments to the removal timeline may be necessary.

Conclusion

Removing formwork for concrete slabs is a crucial aspect of the construction process that requires careful consideration and adherence to best practices. Proper timing, inspection, and technique are essential to ensure that the concrete remains intact and that the overall quality of the project is not compromised. By following the guidelines outlined in this article, contractors and builders can minimize risks and achieve a successful outcome in their concrete projects.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025