Nov . 24, 2024 01:21 Back to list

OEM Scaffolding Solutions for Efficient Construction and Reliable Support Systems

Understanding the Importance of OEM Scaffolding in Construction

In the dynamic world of construction, the safety and efficiency of building processes are paramount. One integral component that ensures these standards are met is scaffolding. Among the various types of scaffolding available in the market, OEM (Original Equipment Manufacturer) scaffolding stands out as a preferred choice for many construction professionals. This article delves into the significance of OEM scaffolding, its benefits, and how it enhances the construction industry.

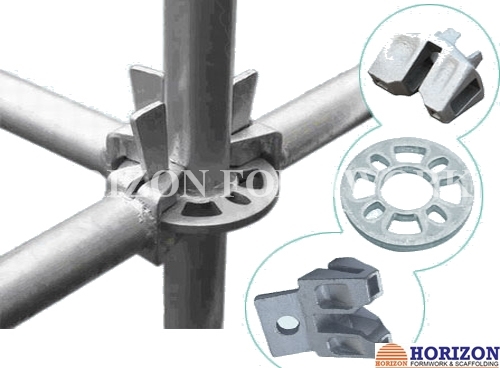

OEM scaffolding refers to scaffolding products manufactured by an original equipment manufacturer that adheres to strict quality regulations and industry standards. This type of scaffolding is designed not just for durability but also for safety during construction projects, which can often pose significant risks. Utilizing OEM products ensures that the scaffolding you use is specifically designed for your project needs, ensuring optimal performance and safety.

Understanding the Importance of OEM Scaffolding in Construction

Additionally, OEM scaffolding typically comes with comprehensive warranties and support, further enhancing its reliability. In the event of a defect or failure, manufacturers are often obligated to provide effective solutions, ensuring that projects can continue with minimal disruption. This contrasts sharply with generic or unbranded scaffolding options, which may lack the same level of accountability and support.

oem scaffold

Another significant benefit of OEM scaffolding is its adaptability. Construction sites vary widely in their requirements — from tall skyscrapers to intricate renovation projects. OEM scaffolding can be customized to fit the specific needs of a project, including various heights, designs, and load capacities. Such customization is vital in ensuring that each project adheres to safety regulations and reduces the risk of accidents due to inadequate support.

Moreover, OEM scaffolding is built with safety features that comply with the latest standards and regulations. Safety should always be the priority on construction sites, and OEM manufacturers are keenly aware of this. They invest in research and innovation to develop scaffolding that not only meets but exceeds safety standards. This forward-thinking approach plays a crucial role in protecting the workers who rely on these structures daily.

The economic benefits of using OEM scaffolding cannot be overlooked. While the initial investment may be higher than that of generic scaffolding, the long-term advantages, such as durability, safety, and warranty support, lead to cost savings. Reduced accidents and associated liabilities can ultimately save companies a significant amount of money, making OEM scaffolding a wise investment in the long run.

In conclusion, OEM scaffolding presents a myriad of advantages that bolster safety, reliability, and efficiency in construction projects. By investing in high-quality, tailored scaffolding solutions, construction professionals can ensure the well-being of their workforce and the success of their projects. Whether a small renovation or a large-scale construction endeavor, OEM scaffolding is an indispensable tool that contributes significantly to the industry's overall durability and safety. As construction continues to evolve, the importance of utilizing top-tier OEM solutions will only become more pronounced, paving the way for safer and more efficient building practices.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025