Nov . 17, 2024 01:08 Back to list

oem timber formwork in construction

The Role of OEM Timber Formwork in Modern Construction

In today's rapidly evolving construction industry, the demand for efficient, cost-effective, and sustainable building materials has never been higher. Among these materials, OEM (Original Equipment Manufacturer) timber formwork has emerged as a critical component in the construction process. This article explores the significance of OEM timber formwork and its impact on the construction sector.

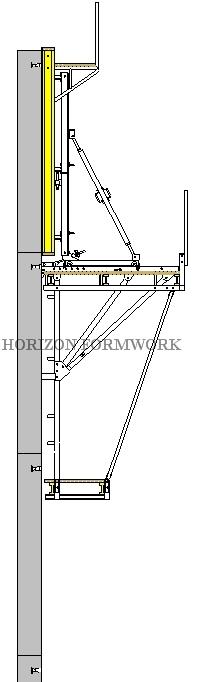

OEM timber formwork refers to pre-engineered wooden structures designed to hold concrete in place until it sets and gains sufficient strength. These formworks are produced by manufacturers specializing in creating high-quality and durable products tailored to meet specific construction needs. The customization aspect allows for various sizes and shapes, catering to the diverse architectural designs and structural requirements of modern buildings.

One of the primary advantages of using OEM timber formwork is its inherent strength and versatility. Timber, as a natural material, offers excellent flexibility, making it suitable for creating complex shapes and curves that other materials might struggle to accommodate. This adaptability is crucial in contemporary architecture, where aesthetic appeal and innovative designs are paramount. Additionally, timber formwork provides a smooth finish to concrete surfaces, reducing the need for extensive post-construction treatment.

Another significant benefit of OEM timber formwork is its lightweight nature compared to traditional materials like steel or concrete. This characteristic not only facilitates easier handling and erection on-site but also reduces labor costs and time during the construction process. Furthermore, the lightweight design minimizes the burden on machinery involved in lifting and positioning the formwork, leading to increased operational efficiency.

oem timber formwork in construction

Sustainability is a pressing concern in the construction industry, and OEM timber formwork aligns closely with eco-friendly practices. Timber is a renewable resource, and when sourced responsibly from managed forests, it can significantly reduce the carbon footprint associated with construction. Many manufacturers prioritize sustainable forestry practices, ensuring that their products contribute positively to the environment. This commitment to sustainability enhances a project's public image, making it more appealing to environmentally conscious clients and investors.

Moreover, OEM timber formwork is often designed for reuse, which further promotes sustainability. After the initial use, the formwork can be refinished or repurposed for other projects, reducing waste and minimizing the demand for new materials. This circular approach not only conserves resources but also presents cost savings for construction companies, as they can rely on existing materials for future projects.

In terms of safety, OEM timber formwork offers superior handling properties, reducing the risk of accidents during installation and dismantling. The stable and secure nature of well-manufactured timber forms enhances worker safety on-site, an essential consideration in construction management.

In conclusion, OEM timber formwork plays a vital role in modern construction, offering a blend of strength, versatility, and sustainability. As the industry continues to embrace innovative practices, the adoption of high-quality timber formwork will likely increase. By leveraging the advantages of OEM timber products, construction firms can enhance their efficiency, reduce costs, and contribute to a more sustainable future. As architects and builders continue to push the boundaries of design, OEM timber formwork will undoubtedly remain a cornerstone of contemporary construction methods, exemplifying the harmonious balance between functionality and aesthetics.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025