Oct . 21, 2024 00:32 Back to list

sustainable plastic formwork solutions for concrete construction suppliers in the industry

The Advantages of Plastic Formwork for Concrete A Revolutionary Solution for Construction Suppliers

In the ever-evolving construction industry, efficiency, sustainability, and cost-effectiveness have become paramount concerns for builders and suppliers. One innovation that has garnered significant attention is plastic formwork for concrete. This material offers distinct advantages over traditional wooden or metal formwork, making it an attractive option for suppliers and contractors alike.

Plastic formwork consists of lightweight, high-strength materials designed specifically for concrete pouring. Unlike conventional wooden or metal forms, which can be heavy, cumbersome, and require extensive maintenance, plastic formwork is much easier to handle and install. This allows construction teams to complete projects faster and with less labor involvement, ultimately reducing costs and increasing productivity.

One of the most significant advantages of plastic formwork is its durability. Plastic forms are resistant to moisture, rotting, and insect damage, which can plague wooden forms. Additionally, plastic does not rust or corrode like metal forms, ensuring a longer lifespan and reduced replacement costs. This resilience makes plastic formwork a smart investment for suppliers looking to provide materials that stand the test of time.

Moreover, plastic formwork is incredibly versatile. It can be used for various concrete applications, including walls, slabs, beams, and columns. Suppliers can offer a comprehensive range of products suited for numerous construction projects, catering to both large-scale commercial developments and smaller residential builds. This versatility not only attracts a broader customer base but also allows suppliers to provide tailored solutions for specific project needs.

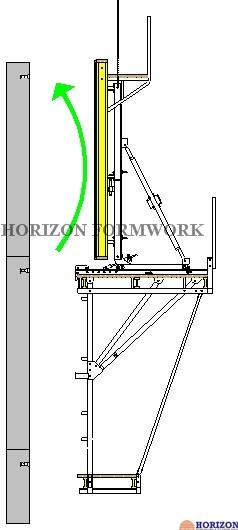

plastic formwork for concrete supplier

From an environmental standpoint, plastic formwork is a more sustainable choice compared to traditional materials. Many manufacturers produce plastic formwork from recycled materials or repurposed plastics, reducing waste and promoting a circular economy. Furthermore, because plastic forms can be reused multiple times (up to several hundred uses), they significantly decrease the amount of material waste generated on job sites. This feature aligns with the global push for greener construction practices, making it an appealing option for environmentally conscious suppliers and builders.

In addition to its physical properties, plastic formwork is also gaining popularity due to its easy maintenance and cleaning. Unlike wood, which can absorb concrete spillage and require extensive cleaning, plastic forms can be quickly washed down after use, reducing downtime between projects. This efficiency can greatly enhance operational workflows for construction firms, making plastic formwork an indispensable component of modern building practices.

It's also important to consider the economic impact of choosing plastic formwork for concrete. By streamlining construction processes and minimizing delays caused by formwork failures, projects can stay on schedule and within budget. For suppliers, offering competitive pricing on these innovative forms can position them favorably in the market, attracting a steady stream of business from builders looking for reliable, high-quality materials.

In conclusion, plastic formwork for concrete presents a transformative approach for suppliers and construction professionals alike. With its durability, versatility, sustainability, and cost-efficiency, it is poised to reshape the landscape of concrete construction. As the demand for modern, efficient building solutions continues to rise, suppliers who embrace plastic formwork will undoubtedly find themselves at the forefront of this exciting evolution in the industry. Investing in these materials is not just about keeping up with trends; it’s about leading the charge toward a more sustainable and efficient future in construction.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025