Oct . 21, 2024 21:25 Back to list

Top Companies Specializing in Plastic Formwork Systems for Construction Industry

The Rise of Plastic Formwork System Companies Transforming Construction Practices

In recent years, the construction industry has seen a significant shift towards more sustainable and efficient building methods. Among the notable innovations is the use of plastic formwork systems. This technology has increasingly gained popularity due to its lightweight nature, durability, and reusability. Companies specializing in plastic formwork systems are emerging as key players in the construction market, revolutionizing traditional practices and addressing environmental concerns.

What is Plastic Formwork?

Plastic formwork is a modern alternative to traditional wooden or metal formwork used in concrete construction. Made from high-quality plastic materials, these systems are designed to mold and support concrete while it sets. They offer several advantages over conventional materials, including reduced weight, easy handling, and minimal maintenance. Furthermore, plastic formwork can be reused multiple times without significant degradation, making it a cost-effective and eco-friendly option for builders.

Advantages of Plastic Formwork Systems

1. Lightweight and Easy to Handle Unlike traditional metal or timber formwork, plastic formwork systems are much lighter, making them easier to transport and assemble. This feature not only speeds up the construction process but also reduces labor costs.

2. Durability Plastic materials are resistant to rot, corrosion, and weather-related damage, ensuring longevity in construction projects. This durability translates to lower replacement costs and less waste over time.

3. Reusability Plastic formwork can be reused many times, making it an economical choice for contractors. With a typical lifespan of over 100 uses, the initial investment can lead to significant savings on future projects.

4. Design Flexibility Plastic formwork systems can be customized to create various shapes and sizes, allowing for more creativity in architectural design. This adaptability enables builders to meet unique project specifications efficiently.

5. Reduced Waste As sustainability becomes a priority in construction, plastic formwork systems contribute to waste reduction. Their longevity and reusability help minimize the environmental footprint associated with formwork disposal and manufacturing.

Leading Plastic Formwork System Companies

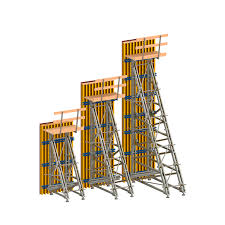

plastic formwork system companies

Several companies have recognized the potential of plastic formwork and have established themselves in this growing market

1. PERI GmbH A global leader in formwork and scaffolding technology, PERI has developed innovative plastic formwork solutions that meet high engineering standards while ensuring cost-efficiency.

2. Alumatec Known for its lightweight plastic formwork, Alumatec combines advanced technology with durable materials to deliver high-performance solutions for both residential and commercial projects.

3. Doka Doka is another prominent player in the formwork industry, providing a range of plastic formwork solutions that offer flexibility and efficiency for project managers looking for modern construction methods.

4. Modular Formwork Systems This company specializes in versatile plastic formwork systems that cater to various construction needs, focusing on enhancing productivity while being environmentally friendly.

The Future of Plastic Formwork Systems

The demand for plastic formwork systems is expected to continue growing as more construction companies recognize the advantages of this innovative technology. With many nations pushing for greener building practices and corporate responsibility, plastic formwork presents a viable solution that aligns with these goals.

Additionally, advancements in material science and engineering will likely enhance the performance of plastic formwork systems, leading to further innovations such as better insulation properties, increased resistance to harsh conditions, and improved customization options.

Conclusion

Plastic formwork system companies are at the forefront of a construction revolution, providing solutions that are as sustainable as they are effective. As the industry evolves, these companies will play a crucial role in shaping the future of building practices, leading to smarter, cleaner, and more efficient construction methods. With their commitment to reducing waste and enhancing productivity, plastic formwork systems represent a significant step towards a more sustainable construction landscape. Embracing this technology will not only benefit the environment but also create opportunities for builders to modernize their practices and achieve greater success in their projects.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025