Aug . 22, 2024 05:53 Back to list

Plywood Formwork Solutions for Construction from Leading Manufacturers in the Industry

The Importance of Plywood Formwork in Construction A Look at Manufacturers

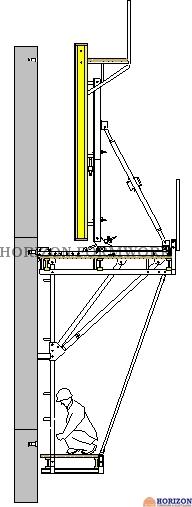

In the realm of construction, formwork is a crucial component that affects the integrity and efficiency of any project. Among various types of formwork materials, plywood has emerged as a preferred choice, particularly for casting concrete structures. The role of plywood formwork manufacturers is vital in delivering high-quality products that meet the diverse demands of construction projects across different scales.

Plywood formwork is renowned for its versatility, strength, and efficiency. Constructed using multiple layers of thin wood veneers, plywood provides a sturdy yet lightweight alternative to traditional formwork materials like steel and concrete. This adaptability allows for easier handling and installation, ultimately reducing labor costs and construction time. Manufacturers of plywood formwork are increasingly exploring innovative designs that enhance usability while maintaining structural integrity.

One of the primary advantages of plywood formwork is its ability to deliver a smooth and uniform surface finish for concrete structures. A good-quality plywood formwork will minimize the need for additional finishing work, leading to significant cost savings. Additionally, plywood’s resilience to water and chemicals ensures that the formwork can withstand harsh construction site conditions while preserving its performance over multiple uses. Leading manufacturers focus on creating products treated for durability, thus extending the lifecycle of the formwork and reducing the environmental impact associated with frequent replacements.

Sustainability has become a hallmark of modern construction practices, and plywood formwork is no exception. Manufacturers are becoming increasingly aware of the need for eco-friendly materials and production processes. Many are adopting sustainably sourced timber and utilizing advanced production methods that reduce waste and energy consumption. This shift not only addresses environmental concerns but also appeals to a market that is becoming more conscious of the ecological footprint of construction materials.

construction plywood formwork manufacturer

Moreover, innovation in technology plays a significant role in shaping the plywood formwork industry. Advanced manufacturing processes, such as computer numerical control (CNC) machining, allow for precise cutting and shaping of plywood components. This precision enhances the quality of the finished product and minimizes errors during installation. Manufacturers are also investing in research and development to explore new techniques, such as prefabrication, which can further streamline construction timelines and improve overall project efficiency.

Partnerships between plywood formwork manufacturers and construction companies are essential for ensuring that products meet specific project requirements. Collaborative efforts can lead to customized solutions tailored to unique architectural designs or challenging site conditions. Such partnerships not only foster innovation but also enable manufacturers to gather valuable feedback from users, driving continuous improvement of their products.

In addition to innovation, quality assurance remains a critical focus for plywood formwork manufacturers. Rigorous testing protocols for materials and finished products are essential to ensure compliance with industry standards and safety regulations. Manufacturers that prioritize quality control can build a solid reputation and gain the trust of their clients, which is invaluable in a competitive marketplace.

In conclusion, plywood formwork manufacturers play a pivotal role in the construction industry. Their commitment to quality, sustainability, and innovation ensures that construction projects are executed efficiently and effectively. As the demand for advanced formwork solutions continues to grow, the role of these manufacturers will remain integral to shaping the future of construction, paving the way for resilient and aesthetically pleasing concrete structures that stand the test of time.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025