Nov . 10, 2024 01:28 Back to list

Plywood Formwork Solutions for Efficient Concrete Construction Projects

The Importance of Plywood Formwork for Concrete Factories

In the construction industry, the efficiency and quality of concrete structures largely depend on the materials and methods used during the building process. One crucial component in this regard is formwork, which provides temporary support to maintain the shape and structure of fresh concrete until it has hardened. Among various types of formwork materials available, plywood has gained prominence due to its versatility, durability, and cost-effectiveness. This article delves into the significance of plywood formwork specifically within concrete factories, exploring its benefits, applications, and best practices.

Versatility of Plywood Formwork

Plywood formwork is utilized extensively in concrete factories due to its adaptability to complex shapes and sizes. Unlike traditional materials such as timber or steel, plywood can be easily cut and shaped to create custom molds that fit specific project requirements. This feature is particularly beneficial for concrete factories, where diverse building projects demand different formwork solutions. From flat surfaces to intricate designs, plywood can accommodate a wide range of applications, making it an ideal choice for both large-scale structures and smaller installations.

Durability and Strength

The performance of plywood in formwork applications is largely attributed to its exceptional durability and strength-to-weight ratio. Plywood is engineered to withstand the substantial weight of wet concrete while also being resistant to warping and splitting. This is particularly critical in a concrete factory setting where maintaining the integrity of the formwork throughout the curing process directly impacts the final product’s quality. Additionally, many plywood options are treated to resist moisture and chemicals, further extending their lifespan and reliability.

Cost-Effectiveness

One of the most compelling advantages of using plywood formwork in concrete factories is its cost-effectiveness. When compared to traditional materials like steel formwork, plywood generally requires a lower initial investment, making it accessible for businesses of varying sizes. Moreover, its lightweight nature reduces transportation and handling costs. Plywood can also be reused multiple times with proper maintenance, allowing factories to maximize their investment over repeated projects. This economic efficiency is vital in an industry where profit margins can be thin, and every cost-saving measure is crucial.

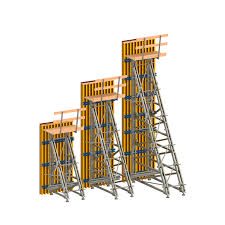

plywood formwork for concrete factory

Quality of Concrete Finish

The choice of formwork significantly influences the finish quality of concrete surfaces. Plywood, specifically phenolic or melamine-faced plywood, is known for producing smooth, high-quality finishes that minimize the need for additional surface treatments. This is essential for concrete factory outputs where aesthetic appeal may be a significant factor. Smooth surfaces reduce the incidence of imperfections, ensuring that the final product meets strict quality standards and customer expectations.

Best Practices for Plywood Formwork

To maximize the advantages of plywood formwork, concrete factories must adopt best practices for installation and maintenance. First, proper sealing of plywood edges is essential to protect against moisture infiltration and extend the formwork's lifespan. Additionally, it is advisable to use appropriate release agents when demolding to minimize damage and ensure easy separation from the cured concrete.

Moreover, regular inspections should be conducted to identify any signs of wear, warping, or damage. Catching such issues early ensures that the formwork remains functional and reliable throughout its use. Finally, training personnel in the correct handling and installation techniques is critical to avoid mishaps that could lead to costly repairs or delays.

Conclusion

In conclusion, plywood formwork plays a vital role in the efficiency and effectiveness of concrete factories. Its versatility, durability, cost-effectiveness, and ability to produce high-quality finishes make it a preferred choice among construction professionals. By understanding best practices for its use and maintenance, concrete factories can not only enhance their operational efficiency but also improve the overall quality of their concrete products. As the construction industry continues to evolve, the integration of advanced materials like plywood in formwork will undoubtedly propel the sector towards greater innovation and sustainability.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025