Oct . 06, 2024 10:12 Back to list

quick formwork factory

Quick Formwork Factory Revolutionizing Construction Efficiency

In the modern era of construction, time and efficiency are paramount. One of the most innovative advancements that have emerged to meet these demands is the quick formwork system. At the heart of this innovation lies the quick formwork factory, a specialized facility dedicated to producing high-quality formwork solutions designed to streamline building processes. This article explores the significance, processes, and benefits of quick formwork factories in today’s construction landscape.

Understanding Quick Formwork

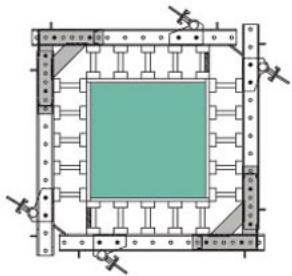

Formwork refers to the molds used to shape concrete into required structures, such as walls, slabs, and foundations. Traditional formwork systems often involve labor-intensive processes and considerable time to erect and dismantle. Quick formwork, on the other hand, employs modern materials and designs that significantly reduce the time needed for these procedures. Quick formwork systems are typically made from lightweight materials, such as aluminum or engineered plastics, which facilitate easier handling and installation.

The Role of Quick Formwork Factories

Quick formwork factories play a crucial role in producing these advanced formwork systems. Situated strategically near construction sites or in industrial hubs, these factories are equipped with state-of-the-art technology and machinery to manufacture formwork components with precision. Production processes often include cutting, shaping, and assembling materials in a controlled environment, ensuring consistency and high-quality output.

Moreover, quick formwork factories focus on innovation and are often at the forefront of research and development, continually improving their products to meet the evolving needs of the construction industry. They also offer customization options, enabling contractors to order tailored solutions that fit specific project requirements.

Benefits of Quick Formwork from Factories

1. Time Efficiency The primary advantage of quick formwork systems is their time-saving capabilities. With modular designs that allow for rapid assembly and disassembly, construction projects can progress at a much faster rate, significantly reducing labor costs and overall project timelines.

quick formwork factory

2. Cost-Effectiveness While the initial investment in quick formwork may be higher than conventional forms, the long-term savings are substantial. The reduction in labor hours, minimized material waste, and faster project completion ultimately lead to lower construction costs.

3. Enhanced Safety Quick formwork systems are designed with safety in mind. Their lightweight materials and modular components reduce the risks associated with handling heavy formwork. Additionally, the speed of installation minimizes the time workers are exposed to potential hazards on-site.

4. Sustainability Many quick formwork factories prioritize eco-friendly practices, utilizing recyclable materials and efficient production methods that minimize waste. This aligns with the growing emphasis on sustainability within the construction industry, making quick formwork a more environmentally friendly option compared to traditional methods.

5. Versatility Quick formwork can be used in a variety of construction applications, from residential buildings to large commercial projects. This versatility allows construction companies to leverage the same formwork system across different projects, further enhancing the return on investment.

Future Trends in Quick Formwork Factories

As we move further into the 21st century, quick formwork factories will likely continue to evolve. The integration of advanced technologies, such as automation and artificial intelligence, will enhance production efficiencies and product customization. Additionally, the development of new materials, including composites and smart materials, will expand the capabilities and applications of quick formwork systems.

Furthermore, as the demand for sustainable construction practices increases, quick formwork factories will play an essential role in promoting environmentally responsible building solutions. Innovations that focus on recyclability and minimal environmental impact will become increasingly critical for the future of construction.

Conclusion

Quick formwork factories are transforming the construction industry by providing efficient, cost-effective, and versatile solutions that meet the demands of modern building projects. As they continue to innovate and adapt to changing market needs, these factories will be instrumental in shaping the future of construction. By embracing the benefits of quick formwork, contractors can improve productivity, enhance safety, and contribute to sustainable building practices, making way for a more efficient construction landscape. The future looks promising for quick formwork and its factories, as they remain at the forefront of construction efficiency.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025