Nov . 19, 2024 19:37 Back to list

scaffold metal planks manufacturer

Importance of Scaffold Metal Planks in Construction A Manufacturer's Insight

In the ever-evolving landscape of construction, safety and efficiency are paramount. Among the various components that contribute to these objectives, scaffold metal planks play a critical role. As a manufacturer of scaffold metal planks, it is essential to understand not only the product itself but also its significance within the construction sector. This article will delve into the importance of scaffold metal planks, their manufacturing process, and their contributions to safety and productivity on job sites.

What Are Scaffold Metal Planks?

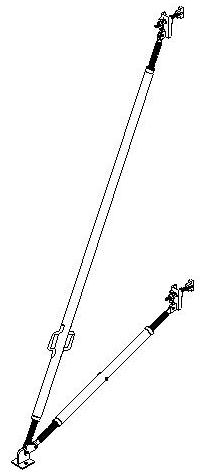

Scaffold metal planks are horizontal platforms used in scaffolding systems to create work surfaces for construction and maintenance activities. These planks are generally made from high-strength materials, such as aluminum or steel, which provide durability and support for workers and equipment. Given their central role in scaffolding systems, the quality and design of metal planks are pivotal in ensuring worker safety and compliance with industry standards.

Safety Regulations and Standards

The construction industry is heavily regulated, and scaffolding materials, including metal planks, must meet stringent safety standards. Various organizations, such as the Occupational Safety and Health Administration (OSHA) in the United States and the European Committee for Standardization (CEN) in Europe, have established guidelines to protect workers. As a manufacturer, adhering to these regulations is not just a legal obligation but a commitment to quality and safety. This involves rigorous testing and certification processes to ensure that the planks can withstand the weight and stress encountered during regular use.

Manufacturing Process

The manufacturing of scaffold metal planks involves several critical steps that ensure the final product is robust and reliable. It begins with the selection of high-quality raw materials, typically aluminum or steel, chosen for their strength-to-weight ratio. The manufacturing process includes

1. Cutting Raw materials are cut to specific dimensions to meet the design specifications of scaffold planks. 2. Forming The cut pieces are then shaped using advanced techniques such as pressing or rolling to achieve the desired structural properties.

scaffold metal planks manufacturer

3. Welding or Joining For added strength, components are welded or mechanically joined, ensuring a secure and stable structure.

4. Surface Treatment The planks undergo surface treatment processes, such as anodizing for aluminum or galvanizing for steel, to enhance corrosion resistance and durability.

5. Quality Control Once manufactured, each batch of planks is subjected to rigorous quality control tests, including load testing, to ensure they meet safety standards.

Benefits of Scaffold Metal Planks

One of the primary advantages of using metal planks in scaffolding is their strength and durability. Unlike wooden planks, which may warp or rot over time, metal planks maintain their integrity, providing a reliable platform for workers. This reliability reduces the risk of accidents on-site, contributing to overall workplace safety.

Moreover, metal planks are lightweight, making them easier to handle and transport. This characteristic enhances efficiency during the setup and dismantling of scaffolding structures, ultimately saving time and labor costs. Additionally, their modular design allows for versatile applications across various construction projects, from residential buildings to large-scale industrial facilities.

Conclusion

As a manufacturer of scaffold metal planks, the focus should always be on producing high-quality, reliable products that prioritize safety and efficiency. The role of scaffold metal planks in construction cannot be overstated; they are vital to ensuring that workers can perform their tasks safely and effectively. By understanding the importance of rigorous manufacturing standards and adhering to safety regulations, manufacturers can help propel the construction industry forward. As projects continue to demand more robust, efficient, and safe scaffolding solutions, the importance of scaffold metal planks will only continue to grow, solidifying their place as an essential component in modern construction practices.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025