Oct . 14, 2024 17:28 Back to list

Exploring Innovative Exporters for Scaffold Platform Solutions in Construction Industry

The Evolution of Scaffold Platform Exporters

In the realm of construction and industrial maintenance, scaffold platforms play a pivotal role in ensuring safety and efficiency. As global demand for these structures grows, scaffold platform exporters have emerged as critical players in the supply chain. This article explores the evolution of scaffold platform exporters, their importance in the industry, and the trends shaping their future.

Historical Context

Scaffold platforms have been used for centuries, originating from ancient construction methods where wooden platforms were erected to facilitate building. Over time, the materials and designs have evolved significantly, with innovations leading to the introduction of metal scaffolding. This advancement not only improved durability and safety but also increased the efficiency of construction projects. As globalization took hold, scaffold manufacturers began exporting their products, giving rise to a new industry of scaffold platform exporters.

The Role of Scaffold Platform Exporters

Scaffold platform exporters are essential in the construction sector. They bridge the gap between manufacturers and construction sites worldwide. By procuring scaffolding materials from manufacturers, these exporters ensure that builders, contractors, and industrial operators have access to high-quality scaffolding systems that meet local regulations and safety standards.

One of the key advantages of working with scaffold platform exporters is their ability to provide tailored solutions. Different regions have varying requirements based on local building codes, environmental conditions, and project specifications. Exporters with in-depth market knowledge can offer customized products that align with these needs, ensuring compliance and enhancing safety.

Market Trends

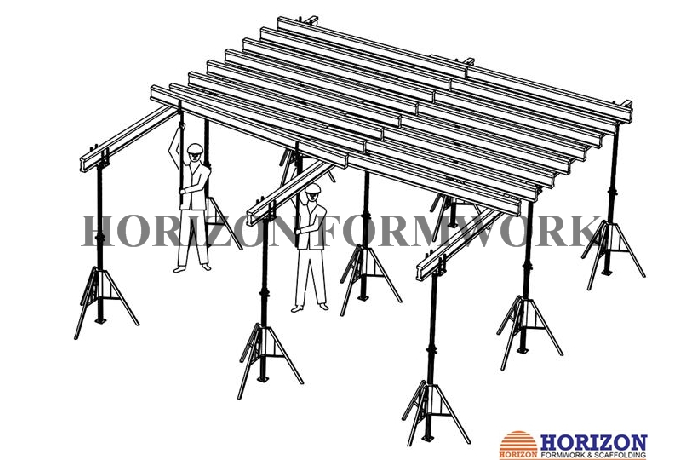

scaffold platform exporters

The scaffold platform export market is currently influenced by several trends. First, sustainability has become a crucial aspect of construction. Eco-friendly materials and practices are in high demand, prompting exporters to seek out green alternatives for their scaffolding products. Manufacturers are increasingly offering recyclable scaffolding materials and systems designed to minimize waste during construction.

Secondly, technological innovation is reshaping the industry. The rise of modular scaffolding systems allows for quicker assembly and disassembly, significantly reducing labor costs and time on site. Exporters who embrace these innovations can offer enhanced products that improve productivity and safety for their clients. Furthermore, advancements in digital technologies, such as Building Information Modeling (BIM), are being integrated to streamline processes from design to execution.

Global Supply Chain Challenges

Despite the positive outlook, scaffold platform exporters face several challenges in the global supply chain. The COVID-19 pandemic underscored vulnerabilities, leading to disruptions in manufacturing and shipping processes. Additionally, fluctuating raw material prices and trade tariffs can impact costs and availability.

To navigate these challenges, exporters are adopting more resilient strategies. Many are diversifying their supplier networks to mitigate risks associated with reliance on specific regions. Furthermore, enhancing warehousing capabilities and optimizing logistics can help buffer against future disruptions.

Conclusion

The role of scaffold platform exporters in the construction industry is increasingly critical as global projects grow in scale and complexity. By understanding market trends, embracing sustainability, and leveraging technology, these exporters can continue to thrive despite challenges. As the demand for safe and efficient scaffolding solutions expands, the evolution of scaffold platform exporters will remain a vital component of the construction landscape, ensuring that projects are completed effectively and safely around the world.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025