Dec . 06, 2024 07:30 Back to list

Soffit Formwork Solutions for Efficient Slab Construction and Formwork Systems

The Importance of Slab Soffit Formwork in Construction An Overview

In the realm of construction, the importance of precision, durability, and efficiency cannot be overstated. One of the critical aspects of any structural project, especially in the development of multi-story buildings, is the formwork used during the casting of concrete slabs. Among various formwork systems, slab soffit formwork has emerged as a vital component due to its ability to support the weight of fresh concrete while maintaining the desired shape. In this article, we will explore the intricacies of slab soffit formwork, its advantages, manufacturing processes, and how specialized factories contribute to the construction industry.

Understanding Slab Soffit Formwork

Slab soffit formwork refers to the temporary structure used to support the underside of concrete slabs during the curing process. This formwork not only provides support but also defines the desired surface finish and promotes smooth curing of the concrete. Given the significant loads that concrete structures must bear, the design and material choices for slab soffit formwork are crucial for ensuring structural integrity.

Key Benefits of Slab Soffit Formwork

1. Cost-Effectiveness Efficient formwork systems lead to reduced labor costs and material wastage. By opting for modular designs, contractors can reuse the formwork for multiple projects, resulting in long-term savings.

2. Speed of Construction With modern design and manufacturing, slab soffit formwork can be easily assembled and disassembled. This accelerates the construction process, allowing builders to pour concrete quickly and move on to subsequent phases of the project.

3. Versatility Slab soffit formwork can be adapted to various designs and load requirements. Whether it’s for residential buildings or large commercial structures, the flexibility of the formwork system allows for customized solutions.

4. Enhanced Safety A properly designed formwork system minimizes the risks of accidents on site. Robust support structures ensure that the formwork remains stable under heavy loads, significantly reducing the likelihood of failures or injuries.

Manufacturing of Slab Soffit Formwork

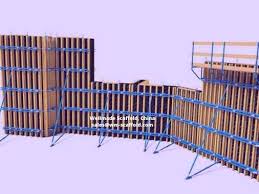

slab soffit formwork factory

The manufacturing process of slab soffit formwork is a detailed operation that combines engineering expertise with advanced technology. Formwork factories play a critical role in producing these systems to meet the high standards required in construction.

1. Material Selection The most commonly used materials for slab soffit formwork include plywood, steel, and aluminum. Each material has its advantages; for instance, plywood is lightweight and offers good insulation, whereas steel provides greater strength.

2. Precision Engineering Formwork components must be designed with precision to ensure seamless assembly and stability. Advanced manufacturing techniques, such as CNC machining, are often employed to create highly accurate parts that fit together perfectly.

3. Quality Control Quality assurance is paramount in formwork manufacturing. Factories often implement rigorous testing procedures to ensure that formwork systems can withstand the stresses of pouring concrete and later loads.

4. Sustainable Practices With an increased emphasis on sustainability, many formwork manufacturers are incorporating eco-friendly practices. This includes the use of recycled materials and processes that minimize waste.

The Role of Formwork Factories

Formwork factories are essential players in the construction ecosystem. They not only supply the necessary components for slab soffit formwork but also provide expertise in design and engineering. Many factories offer customized solutions tailored to specific project requirements, ensuring that construction firms receive the ideal formwork for their needs.

Moreover, these factories often provide training and support for on-site assembly and disassembly of formwork, enhancing overall productivity and safety. By maintaining a close relationship with construction companies, formwork factories can quickly adapt to changing market demands and technological advances.

Conclusion

In conclusion, slab soffit formwork is a critical element in modern construction, providing essential support during the concrete curing process. The advantages of cost-effectiveness, speed, versatility, and safety make it indispensable in building projects of all sizes. As manufacturing techniques and materials evolve, the role of formwork factories continues to be pivotal in ensuring that the construction industry meets the demands of efficiency and sustainability. With ongoing innovations, the future of slab soffit formwork looks promising, laying the foundation for safer and more efficient-building practices.

-

Adjustable Heavy Duty Props for Slab Formwork - Max Load & Safety

NewsAug.30,2025

-

Premium Formwork Wing Nuts & Tie Rods | Factory Supplier

NewsAug.29,2025

-

Expert Ringlock Scaffolding: Durable, Safe, Efficient Solutions

NewsAug.28,2025

-

Ringlock Scaffolding: Strong, Safe & Efficient Solutions

NewsAug.27,2025

-

OEM Column Formwork: Circular, Curved & Inclined Solutions

NewsAug.26,2025

-

Premium Scaffolding Jacks: Stable, Adjustable & Durable

NewsAug.25,2025