Aug . 05, 2024 03:02 Back to list

Support Systems for Beam Manufacturing and Formwork Solutions for Construction Projects

Formwork Support for Beam Manufacturing A Comprehensive Overview

Formwork support plays a crucial role in the manufacturing of beams within the construction industry. As structures become more complex and demanding in terms of design and safety, the need for reliable and efficient formwork solutions has intensified. This article will explore the significance of formwork support in beam manufacturing, discussing its types, benefits, and best practices.

Understanding Formwork Support

Formwork is a temporary or permanent mold used to shape and support concrete until it gains sufficient strength to bear its own weight. In beam manufacturing, formwork support provides the necessary structure to hold the concrete in place while it cures. The quality of formwork significantly affects the final product, influencing factors such as dimensional accuracy, surface finish, and structural integrity.

Types of Formwork Support

There are various types of formwork support systems available for beam manufacturing. The choice of formwork can depend on several factors, including the size and shape of the beam, the complexity of the design, and specific construction requirements. Common types include

1. Traditional Timber Formwork This is one of the most widely used methods. Timber is cut and assembled on-site to create the desired shape. While it is cost-effective and flexible, it also has limitations in terms of durability and labor intensity.

2. Steel Formwork Steel formwork is known for its strength, durability, and ability to produce high-quality finishes. It is reusable and can be prefabricated, which can save time and reduce labor costs.

3. Aluminium Formwork Similar to steel, aluminum formwork is lightweight and offers excellent durability. It is often used for high-rise construction projects due to its strength and ease of handling.

4. Plastic Formwork This innovative option is becoming increasingly popular due to its lightweight characteristics and resistance to moisture. It can be an excellent choice for projects with complex shapes, offering flexibility in design.

5. Composite Formwork Combining various materials, composite systems provide unique benefits, including enhanced durability, weight savings, and better thermal insulation. They can also be customized to meet specific project demands.

Benefits of Reliable Formwork Support

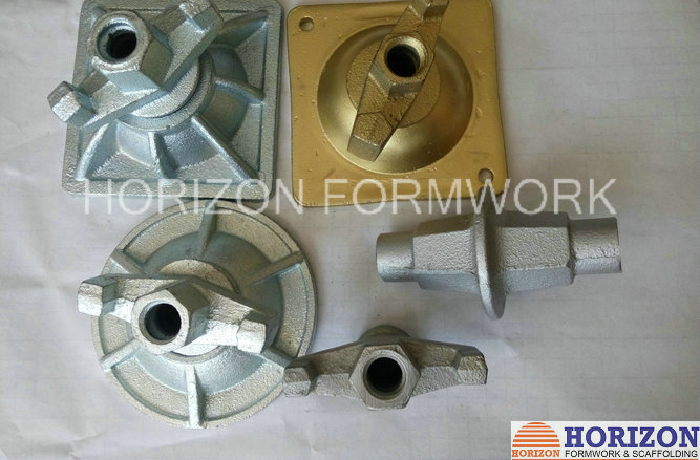

formwork support for beam manufacturer

Implementing an effective formwork support system brings numerous advantages to the beam manufacturing process

- Accuracy and Precision Well-designed formwork ensures that the dimensions of the beam are exact, which is crucial for structural integrity and safety. - Time Efficiency Standardized formwork systems can significantly speed up the construction process. Prefabricated options reduce on-site labor and associated costs.

- Quality Control Consistent formwork leads to uniformity in production, reducing defects and improving the overall quality of the beams.

- Cost-Effectiveness Although the initial investment in formwork can be high, long-term savings can be achieved through reduced labor costs and minimized material wastage.

Best Practices for Formwork Support in Beam Manufacturing

To maximize the benefits of formwork support, manufacturers should consider several best practices

1. Careful Planning Proper planning is essential to determine the most suitable formwork type based on project specifications and requirements.

2. Regular Maintenance Ensuring that formwork is properly maintained can extend its lifespan and improve the quality of the beams produced.

3. Training and Safety Providing training for workers on the proper handling and installation of formwork is critical for safety and efficiency on the job site.

4. Monitoring Conditions Environmental factors such as temperature and humidity can impact the curing process. Monitoring these conditions can lead to better outcomes in beam strength and durability.

In conclusion, formwork support for beam manufacturing is a vital component of the construction industry. By understanding its importance and applying best practices, manufacturers can enhance the quality, efficiency, and safety of their beam production processes, ultimately leading to more robust and durable structures.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025