Nov . 19, 2024 23:22 Back to list

swivel jack scaffolding factories

Understanding Swivel Jack Scaffolding A Perspective on Factories and Production

In the realm of construction and building maintenance, scaffolding plays a crucial role in ensuring safety and efficiency. Among the various scaffolding systems available, swivel jack scaffolding has emerged as a popular choice for contractors and builders alike. This article will explore the concept of swivel jack scaffolding, focusing on its design, functionality, and the factories that manufacture these essential tools.

Swivel jack scaffolding is characterized by its adjustable base, which allows for precise leveling on uneven surfaces. This adaptability is particularly valuable when working in varied environments, such as construction sites with fluctuating topographies. The 'swivel' component refers to the ability of the jack to rotate, providing it with enhanced maneuverability. This feature not only facilitates easy installation but also augments the stability of the scaffolding structure, reducing the risk of accidents during construction activities.

The Design and Functionality of Swivel Jack Scaffolding

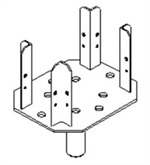

The basic design of swivel jack scaffolding consists of several key components, including vertical standards, horizontal ledgers, and the swivel jacks themselves. The vertical standards form the backbone of the scaffolding system, while the horizontal ledgers provide essential support. The swivel jack, positioned at the base of the vertical standards, allows for height adjustments and ensures that the scaffolding remains level, regardless of the underlying surface conditions.

Swivel jacks are typically made from high-strength materials, such as galvanized steel or aluminum, to withstand the rigors of construction environments. Their robust construction ensures durability, which is a vital characteristic for any scaffolding system. Additionally, the swivel mechanism incorporates a locking system that secures the jack in place once the desired height is achieved, further enhancing the safety of the structure.

The Role of Factories in Scaffolding Production

The production of swivel jack scaffolding is an intricate process that involves several stages. Factories specializing in scaffolding manufacture these components with a focus on precision engineering and quality control. The manufacturing process begins with the selection of high-grade raw materials, which are then subjected to rigorous testing to ensure they meet industry standards.

swivel jack scaffolding factories

Once the materials are approved, they undergo various processes, such as cutting, welding, and galvanizing. Cutting machines accurately size the components, while automated welding systems ensure strong joints that can withstand significant loads. After assembly, the scaffolding components are galvanized to protect against corrosion, extending the lifespan of the scaffolding.

Quality assurance is a critical aspect of manufacturing swivel jack scaffolding. Most factories implement stringent inspection protocols throughout the production process. This often involves testing the strength and durability of the jacks, as well as ensuring all components are free of defects. Factories may also adhere to international standards, such as ISO 9001, to guarantee that their scaffolding systems are safe and reliable for end-users.

Market Demand and Trends

The demand for swivel jack scaffolding is on the rise, driven by an ever-growing construction sector across the globe. With the increasing complexity of modern architectural designs and the need for safer work environments, builders are investing in advanced scaffolding solutions. This trend has prompted many factories to innovate continuously, developing new designs and technologies that enhance the efficiency and safety of their products.

Moreover, the emphasis on sustainability in construction has led factories to explore eco-friendly practices in manufacturing. This shift includes using recyclable materials and reducing waste during the production process. By aligning with these trends, factories can meet the evolving demands of the construction industry while contributing to environmental conservation.

Conclusion

Swivel jack scaffolding represents a significant advancement in scaffolding technology, offering versatility, safety, and ease of use. The factories that produce these essential components play a vital role in the construction industry, ensuring that high-quality scaffolding systems are available to meet diverse needs. As the construction landscape continues to evolve, the importance of innovative scaffolding solutions will only grow, highlighting the crucial role of factories in this dynamic field.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025