Nov . 09, 2024 08:58 Back to list

Formwork Solutions for Tie Rod Construction in Factory Settings

The Importance of Tie Rods in Construction Formwork A Look at Factories Producing These Essential Elements

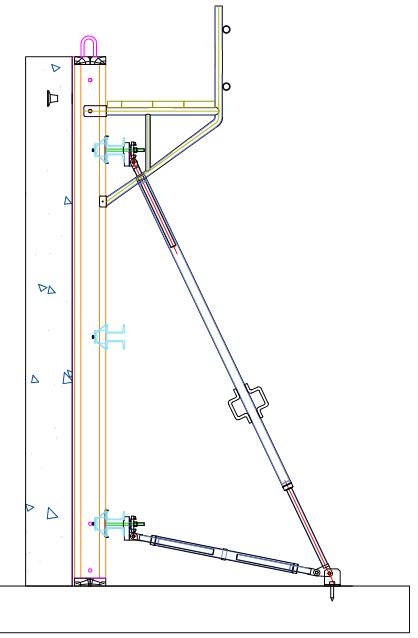

Construction formwork is a critical aspect of the building industry, serving as a temporary structure that supports the pouring of concrete until it hardens. One of the essential components in formwork systems is the tie rod. These rods play a significant role in providing stability and alignment to the concrete molds. Understanding the manufacturing process of tie rods and their importance can shed light on their contribution to successful construction projects.

What are Tie Rods?

Tie rods are elongated, sturdy metal rods that are used to connect different parts of formwork systems. They help maintain the formwork panels in the correct position under the pressure exerted by liquid concrete. By keeping the panels from bowing outward, tie rods help to ensure that the final structure has the desired dimensions and stability.

The Role of Factories in Producing Tie Rods

Factories specializing in tie rod production focus on creating high-quality components that can withstand the stresses of construction sites. The manufacturing process typically begins with the selection of raw materials, often high-strength steel, which is known for its durability and resistance to bending or breaking under load. Once the raw materials are sourced, they go through several stages of production, including cutting, shaping, and surface treatment.

1. Material Selection and Preparation High-quality steel rods are chosen for their tensile strength. The rods are cut to specific lengths based on the design requirements of the formwork system.

2. Shaping and Threading After cutting, the rods are shaped and threaded at both ends. This threading is crucial as it allows the rods to connect securely to other components of the formwork system, such as nuts and washers.

3. Surface Treatment To enhance durability and resistance to corrosion, tie rods undergo various surface treatments. Common methods include galvanization, where a zinc coating is applied, and painting, which adds a protective layer.

tie rod construction formwork factories

4. Quality Control Ensuring that tie rods meet industry standards is crucial. Factories implement stringent quality control measures at every stage of production, including tensile testing, dimensional checks, and visual inspections. This guarantees that the tie rods produced are reliable and safe for use in construction.

Benefits of Using High-Quality Tie Rods

Using high-quality tie rods directly impacts the efficiency of the construction process and the integrity of the final structure. Some of the primary benefits include

- Increased Stability Well-manufactured tie rods help stabilize the formwork, preventing any deformation during the concrete pouring process. This stability is essential for maintaining the intended shape of the structure.

- Improved Safety Strong, reliable tie rods reduce the risk of formwork failure, which can lead to accidents on-site. By ensuring that all components are secure, risks to construction workers and the integrity of the project are minimized.

- Cost Efficiency Investing in quality tie rods that can withstand numerous uses can lead to significant cost savings over time. While cheaper options may be available, they can result in failures or additional replacements, ultimately increasing overall costs.

- Enhances Project Outcome The use of robust tie rods contributes to a smoother construction process, allowing for better planning and execution. When formwork is stable and reliable, it enhances the overall quality of the completed structure.

Conclusion

In summary, tie rods are an invaluable part of construction formwork, and the factories that produce them play a crucial role in ensuring the success of building projects. Through careful manufacturing processes and stringent quality control, these factories provide essential components that enhance the stability, safety, and efficiency of construction. As the demand for construction projects continues to grow, the importance of high-quality tie rod production remains paramount in the industry. Investing in reliable formwork components will lead to safer and more effective construction practices.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025