Oct . 21, 2024 03:03 Back to list

Timber Column Formwork Suppliers and Manufacturers for Construction Projects

The Evolution and Significance of Timber Column Formwork Manufacturers

In the ever-evolving construction industry, the choice of formwork materials significantly impacts the cost, efficiency, and sustainability of building projects. Among the plethora of formwork options available, timber column formwork stands out for its versatility, cost-effectiveness, and sustainability. Timber column formwork manufacturers play a crucial role in the construction sector by providing high-quality, durable, and adaptable formwork solutions that cater to varying construction needs.

Understanding Timber Column Formwork

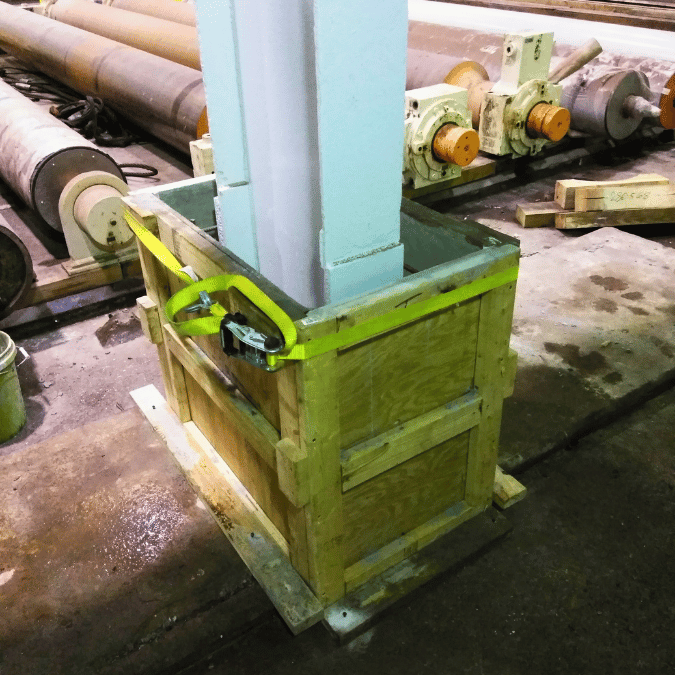

Timber column formwork refers to temporary structures made from timber that support liquid concrete until it hardens and attains the necessary strength. This type of formwork is primarily used to create columns, beams, and other vertical elements in a building. Its primary advantages include easy handling, quick assembly, and minimal waste generation, making it a preferred choice for both large-scale and small-scale projects.

The Role of Timber Column Formwork Manufacturers

Timber column formwork manufacturers are tasked with producing formwork solutions that are not only robust and reliable but also compliant with industry standards. They are responsible for sourcing quality timber, designing formwork systems that facilitate easy installation and dismantling, and ensuring that the products can withstand the pressures exerted by curing concrete. These manufacturers must balance functionality with aesthetics, as many end-users desire formwork solutions that leave appealing finishes post-construction.

Innovations in Timber Column Formwork

The timber formwork sector has seen significant innovations in recent years, driven by advancements in construction technology and a growing emphasis on sustainability. For instance, manufacturers are now exploring engineered wood products, such as laminated veneer lumber (LVL) and cross-laminated timber (CLT), which offer enhanced strength and durability compared to traditional sawn timber. This shift allows construction companies to utilize timber formwork for taller and more complex structures.

Moreover, the integration of digital tools and software for formwork design and planning has revolutionized how manufacturers operate. Advanced modeling tools allow for precise calculations of formwork requirements, which minimizes material waste and ensures efficient use of resources. Manufacturers can now produce customized solutions tailored to specific project needs, optimizing both time and costs.

timber column formwork manufacturers

Sustainability and Environmental Considerations

Sustainability is becoming increasingly important in the construction industry. Timber, being a renewable resource, aligns with sustainable building practices. Responsible sourcing of timber and adherence to environmental certifications, such as the Forest Stewardship Council (FSC) standards, have become essential for many timber column formwork manufacturers. By using sustainably sourced materials, manufacturers not only reduce their environmental footprint but also appeal to environmentally conscious clients.

The ability to reuse timber formwork is another commendable characteristic that manufacturers are promoting. Quality timber formwork can be disassembled and reused for multiple projects, further minimizing waste and optimizing resource utilization. This not only makes economic sense but also supports the circular economy ethos that many modern businesses strive to uphold.

Challenges Facing Timber Column Formwork Manufacturers

Despite the numerous advantages of timber column formwork, manufacturers face certain challenges. Fluctuations in timber prices can impact production costs, forcing manufacturers to adapt their pricing strategies. Additionally, competition from alternative formwork materials such as steel and plastic is intense, requiring timber manufacturers to highlight the unique benefits of timber while maintaining competitive pricing.

Another challenge is educating construction professionals on the benefits and capabilities of modern timber formwork solutions. There is a need for ongoing training and dissemination of information regarding best practices in formwork design and application to ensure that the advantages of timber formwork are fully realized.

Conclusion

Timber column formwork manufacturers are vital contributors to the construction industry, providing solutions that support efficiency, cost-effectiveness, and sustainability. As the industry continues to evolve, these manufacturers must embrace innovation and sustainability practices to meet the ever-changing demands of construction. By doing so, they not only enhance the performance of their products but also contribute to a more sustainable future for the construction sector. The continued evolution of timber column formwork will undoubtedly play a significant role in shaping the buildings and infrastructure of tomorrow.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025