Nov . 24, 2024 13:41 Back to list

Exporters of Timber Wall Formwork Solutions for Construction Industries

Timber Wall Formwork Exporters An Overview of the Industry

The construction sector has undergone significant transformations over the years, with technology playing a pivotal role in enhancing efficiency and reducing costs. One of the essential components in the construction process, especially in concrete work, is formwork. Among the various types of formwork available, timber wall formwork remains a preferred choice for many contractors and builders. This article delves into the timber wall formwork industry, particularly focusing on exporters, their offerings, and the overall impact on global construction markets.

The Significance of Timber Wall Formwork

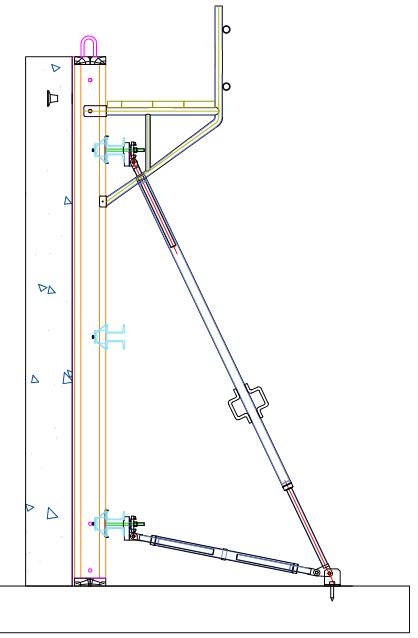

Timber wall formwork provides optimal flexibility and strength for concrete pourings, enabling the creation of complex shapes and structures. This formwork system consists of timber panels and supports that can be easily assembled and disassembled, making it a versatile choice for various construction projects, from residential buildings to large infrastructure works. The lightweight nature of timber combined with its strength ensures that it can support substantial weight while also being easy to handle.

Additionally, timber is a renewable resource, making it an environmentally friendly option compared to some other materials used for formwork. Its ability to be reused multiple times also contributes to sustainability in construction practices. As the global focus on sustainable construction grows, timber wall formwork has gained increased interest from contractors looking to minimize environmental impact while maximizing performance.

The Role of Exporters in the Timber Wall Formwork Market

As demand for timber wall formwork continues to rise, many companies around the world are stepping up as exporters of this essential construction material. Timber wall formwork exporters play a crucial role in the supply chain, connecting manufacturers with construction companies across different regions. They work to ensure that clients have access to high-quality formwork products that meet specific requirements and standards.

These exporters often source timber from sustainable forests and are committed to ethical sourcing practices. By working closely with manufacturers, they can offer a wide range of formwork solutions, catering to various construction needs. The ability to provide customized formwork panels tailored to unique project specifications is a significant advantage offered by many exporters. This adaptability helps construction companies optimize performance and efficiency on-site.

Key Trends in the Timber Wall Formwork Export Market

timber wall formwork exporters

The timber wall formwork export market is characterized by several key trends that are shaping its future. Firstly, there is a growing preference for prefabricated formwork systems. These systems are manufactured off-site and assembled on site, significantly reducing construction time and labor costs. Exporters that offer prefabricated solutions are likely to see an increase in demand.

Secondly, technological advancements are influencing the timber wall formwork industry. The integration of design software and modeling tools allows exporters and manufacturers to optimize the production processes, leading to improved precision and quality. Additionally, advancements in the treatment of timber can enhance durability and resistance to environmental factors, further benefiting construction projects.

Furthermore, as international construction markets expand, exporters are exploring new opportunities in emerging economies. Countries undergoing rapid urbanization and infrastructure development present significant prospects for timber wall formwork exporters. However, these exporters must navigate varying regulations and standards in different regions, which can pose challenges.

Challenges Faced by Timber Wall Formwork Exporters

Despite the opportunities, timber wall formwork exporters also face certain challenges. Fluctuating timber prices due to changing global demand and supply can impact profitability. Moreover, competition from alternative materials, such as steel and plastic formwork, is intensifying. While timber has advantages, businesses must continuously innovate and demonstrate the benefits of timber wall formwork to maintain market share.

Another challenge is the need for compliance with environmental regulations, which can vary between countries. Exporters must be diligent in ensuring that their sourcing practices align with international standards, which may require additional oversight and auditing processes.

Conclusion

In conclusion, timber wall formwork exporters play a vital role in the construction industry by providing essential materials that contribute to efficient and sustainable building practices. As the demand for environmentally friendly construction solutions continues to rise, the timber wall formwork market is poised for growth. By leveraging innovation, maintaining high-quality standards, and adapting to changing market dynamics, exporters can navigate challenges and capitalize on opportunities in this evolving landscape. The future of timber wall formwork is bright, promising significant contributions to both the construction industry and environmental sustainability.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025