Aug . 12, 2024 22:00 Back to list

Top Manufacturers of High-Quality Steel Formworks for Construction and Civil Engineering Projects

The Rise of Steel Formworks Manufacturers Transforming Construction

In the modern construction industry, the demand for efficient, durable, and sustainable materials is on the rise. Among these materials, steel formworks have emerged as a key component in providing structural integrity and support during the construction process. With this growing demand, the role of steel formworks manufacturers has gained significant importance, leading to innovations that have transformed the landscape of construction practices.

What is Steel Formwork?

Steel formwork refers to the use of steel frames, plates, and panels to shape and support concrete until it gains sufficient strength to support itself. Unlike traditional wood formwork, steel formworks offer numerous advantages, including increased durability, reusability, and precision. They can be designed to create a variety of shapes and structures, making them adaptable for various construction projects, from residential buildings to large-scale commercial complexes.

Benefits of Steel Formwork

One of the most notable benefits of steel formwork is its durability. Steel materials can withstand harsh weather conditions and excessive wear and tear, allowing for multiple uses over time. This not only reduces the cost associated with purchasing new formwork for each project but also minimizes waste, contributing to a more sustainable construction process.

Additionally, steel formworks can provide superior dimensional accuracy compared to traditional wooden forms. This precision leads to better-quality concrete finishes and reduces the need for extensive post-construction refinishing. Furthermore, the speed of assembly and disassembly of steel formworks can significantly shorten project timelines, enabling contractors to deliver projects more efficiently.

Innovation in Manufacturing

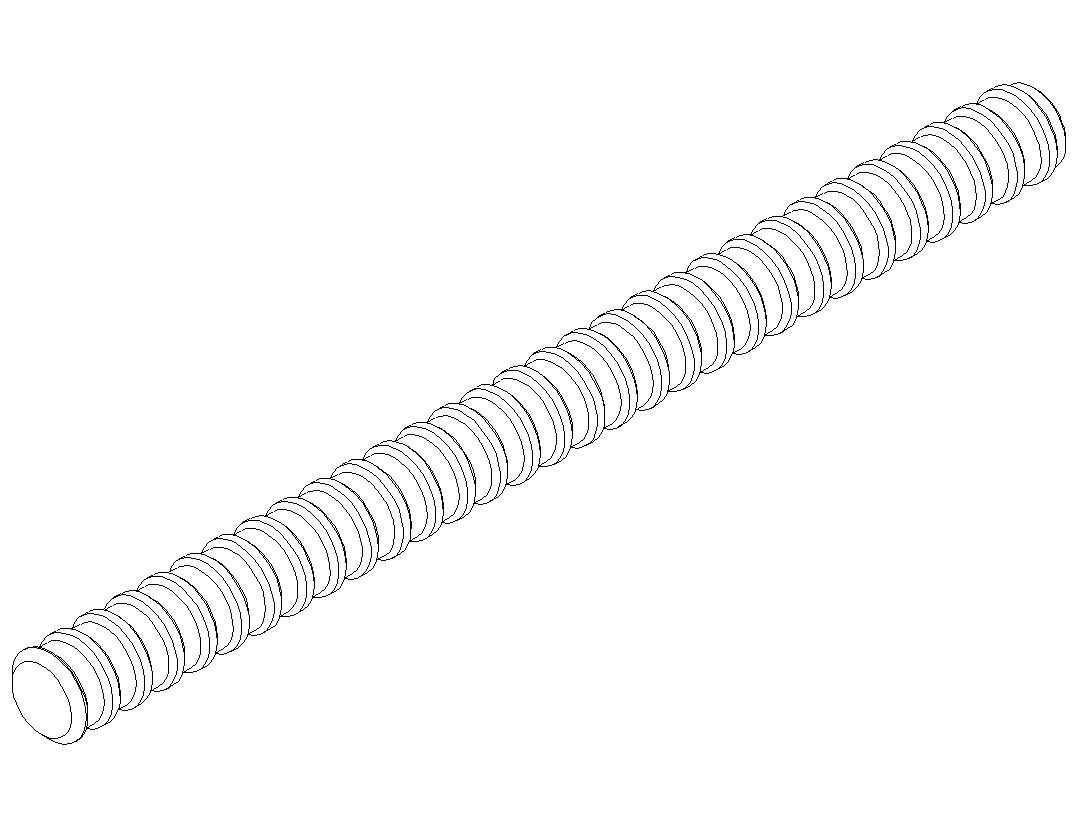

steel formworks manufacturers

The steel formworks manufacturing industry has also seen considerable innovation in recent years. Advanced technologies, such as automated cutting and welding systems, have improved the manufacturing process, enhancing both productivity and safety. Manufacturers are now able to produce formworks that are lighter, easier to handle, and more adaptable to various construction scenarios.

Moreover, the integration of computer-aided design (CAD) in the manufacturing process has allowed for more sophisticated and customized designs. This technological advancement enables manufacturers to meet the specific needs of a project, whether that involves creating unique shapes or accommodating specific load capacities.

Sustainability in Focus

As the construction industry becomes increasingly aware of its environmental impact, many steel formworks manufacturers are adopting sustainable practices. This includes sourcing steel from recycled materials and implementing energy-efficient manufacturing processes. By focusing on sustainability, these manufacturers not only reduce their carbon footprint but also appeal to clients who prioritize eco-friendly practices in their projects.

The Future of Steel Formwork Manufacturing

The future of steel formworks manufacturing looks promising, driven by the growing construction market and the ongoing need for innovative building solutions. With urbanization continuing to rise globally, the demand for more efficient construction methodologies will likely accelerate the adoption of steel formworks.

Furthermore, as new materials and technologies emerge, manufacturers will need to stay ahead of the curve by continuously refining their products and processes. Collaboration with architects and engineers will also be crucial to maximize the potential of steel formworks in creating modern, resilient structures.

In conclusion, steel formworks manufacturers are at the forefront of a significant evolution in the construction industry. Their commitment to producing durable, efficient, and sustainable products not only supports the growing demand for quality construction materials but also contributes to a more sustainable future for the built environment. As the construction sector continues to expand, the role of these manufacturers will be critical in shaping the landscapes of cities and communities worldwide.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025