Oct . 14, 2024 19:44 Back to list

vertical slip formwork suppliers

Understanding Vertical Slip Formwork A Guide to Suppliers and Benefits

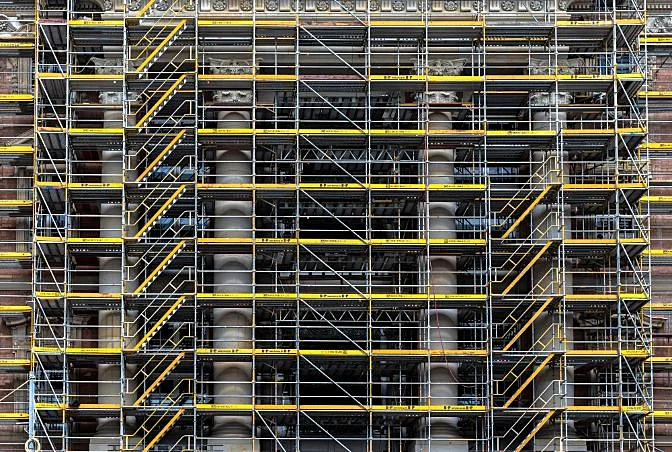

Vertical slip formwork is an innovative construction technique that is gaining popularity in the building industry. This system is particularly useful for constructing vertical structures such as high-rise buildings, silos, and bridges. Unlike traditional formwork methods, vertical slip formwork allows for continuous casting of concrete, enabling efficient and streamlined construction processes. With the growing demand for this technology, an increasing number of suppliers are emerging in the market, each offering unique products and services.

What is Vertical Slip Formwork?

Vertical slip formwork is a specialized formwork system that remains in place during the concrete pouring process, gradually moving upward as the concrete sets. This approach creates a seamless, monolithic structure without the need for repetitive formwork removal and reinstallation. The slip form is usually composed of a series of adjustable panels that align perfectly, ensuring a smooth finish and precise dimensions for the construction project. As the concrete cures, the formwork is lifted slowly, allowing for continuous casting.

Advantages of Vertical Slip Formwork

1. Speed and Efficiency One of the primary benefits of vertical slip formwork is the speed at which it can be implemented. The continuous pouring method significantly reduces the overall construction time. This efficiency is critical for projects that operate under strict deadlines.

2. Cost-Effectiveness Although the initial investment in slip formwork can be higher than traditional methods, the reduced labor costs and shorter project timelines often result in savings. Fewer workers are needed on-site, and the elimination of multiple formwork setups allows for more efficient use of resources.

3. Quality and Precision The use of slip formwork ensures a consistent quality of the concrete structure. It minimizes the risk of defects associated with traditional methods, such as cold joints and misalignment, leading to a stronger and more durable finished product.

4. Versatility Slip formwork can be adapted for various structures, enabling builders to tackle different projects with the same equipment. From skyscrapers to silo structures, this versatility makes it an attractive option for contractors.

vertical slip formwork suppliers

Choosing the Right Supplier

When selecting a supplier for vertical slip formwork, several factors should be considered

- Experience and Reputation Look for suppliers with a strong track record in the industry. Experienced suppliers will not only provide quality products but also valuable insights and recommendations based on past projects.

- Product Range Different projects may require specific slip formwork designs. A supplier that offers a wide range of products can cater to varied project needs, from simple designs to complex applications.

- Technical Support Efficient installation and operation of slip formwork systems require expertise. Ensure that your supplier provides ongoing technical support and guidance throughout the construction process.

- Cost and Value While price shouldn’t be the only factor in selecting a supplier, it’s essential to find a balance between affordability and quality. Compare several suppliers to ensure you’re getting the best value for your investment.

Conclusion

Vertical slip formwork represents a modern solution to the challenges faced in vertical construction. With its numerous advantages, including speed, efficiency, and improved quality, it is becoming the go-to method for many construction projects. As you explore the various suppliers available, consider the factors mentioned above to choose the right partner that can meet your specific needs while delivering a successful construction outcome. The future of vertical construction is leaning towards innovative techniques, and slip formwork is at the forefront of this evolution.

-

High-Quality U Head Jack Scaffolding – Reliable Scaffolding Jack Head Manufacturer & Factory

NewsJul.08,2025

-

High-Quality I Beam H20 Leading Timber Beam H20 Material Factory, Exporters & Manufacturers

NewsJul.08,2025

-

High-Quality Powder Coating Steel Formwork - Durable & Corrosion Resistant Solutions

NewsJul.07,2025

-

Inclined Column Formwork Supplier – Durable & Precise Solutions for Unique Structures

NewsJul.07,2025

-

High-Quality Water Stop Solutions Trusted Water Stop Company & Suppliers

NewsJul.07,2025

-

High-Quality Formwork Material Supplier Reliable Manufacturer & Factory Solutions

NewsJul.06,2025